Content Menu

● What granular activated carbon is

● Regulatory hazard classification

● Health hazards of granular activated carbon

● Oxygen depletion and confined-space hazards

● Combustible dust and fire risk

● Is granular activated carbon hazardous waste?

● Typical PPE and safe handling for GAC

● When granular activated carbon becomes more hazardous

● Comparison: GAC vs PAC hazards

● Practical risk management for granular activated carbon users

● Conclusion

● FAQ About Granular Activated Carbon Hazards

>> 1) Is granular activated carbon toxic to humans?

>> 2) Can granular activated carbon cause explosions?

>> 3) Is wet granular activated carbon dangerous?

>> 4) Is spent granular activated carbon always hazardous waste?

>> 5) What PPE is recommended when handling granular activated carbon?

● Citations:

Granular activated carbon is generally classified as a low-toxicity, non-hazardous adsorbent when handled correctly, but it does present specific hazards such as dust irritation, combustible dust risk, oxygen depletion in confined spaces when wet, and potential hazardous classification once it is spent and loaded with contaminants. Understanding these hazards and following proper safety practices allows industries to use granular activated carbon efficiently while protecting workers, facilities, and the environment.[1][2][3][4]

What granular activated carbon is

Granular activated carbon (GAC) is a highly porous form of carbon supplied as granules typically a few tenths of a millimeter to several millimeters in size, designed for fixed beds in water treatment, air and gas purification, and many industrial processes. Granular activated carbon is produced from raw materials such as coal, coconut shell, or wood, then activated to develop extremely high internal surface area that enables powerful adsorption of organic molecules, odors, and certain inorganic species.[4][5][6]

- Granular activated carbon is widely used in drinking water treatment, wastewater polishing, VOC control, solvent recovery, food and beverage, chemical, and pharmaceutical purification.[7][4]

- Typical granular activated carbon grades are engineered for hardness, particle size, and pore structure to balance adsorption performance, pressure drop, and resistance to mechanical abrasion.[5][4]

Regulatory hazard classification

Most safety data sheets describe virgin granular activated carbon as not classified as a hazardous substance under major chemical classification systems, although some note eye or respiratory irritation and combustible dust warnings. Many granular activated carbon products are listed as non-dangerous goods for transport and “non-hazardous” under systems such as GHS, while still requiring workplace controls for dust, oxygen depletion, and fire prevention.[2][8]

- Some granular activated carbon SDS documents indicate no specific health, physical, or environmental hazard classification, and no mandatory hazard labeling, provided the product is used under normal industrial conditions.[8][2]

- Other granular activated carbon specifications add GHS “Warning” statements regarding eye irritation and dust, reflecting minor but manageable risks during handling and transfer.[6][1]

Health hazards of granular activated carbon

Most data sheets describe granular activated carbon as essentially non-toxic by ingestion or inhalation, but note that dust can mechanically irritate eyes, skin, and upper respiratory tract. Granular activated carbon is not generally considered carcinogenic by agencies such as IARC, NTP, or OSHA, although some coal-based grades contain bound crystalline silica and therefore reference silica-related warnings while still not classifying the bonded material itself as a carcinogen.[9][10][1]

- Inhalation of granular activated carbon dust may cause coughing, sneezing, and mild, temporary irritation, with recommended exposure limits typically aligned with “nuisance dust” or “particulates not otherwise classified.”[10][11]

- Eye contact with granular activated carbon dust can lead to slight to moderate irritation or redness, so basic eye protection such as safety glasses is widely recommended in handling instructions.[12][1]

Oxygen depletion and confined-space hazards

One of the most important hazards of granular activated carbon, especially when wet, is its ability to remove oxygen from air in enclosed or confined spaces, potentially leading to dangerously low oxygen levels. Safety information repeatedly warns that wet granular activated carbon in tanks, vessels, or filters can deplete oxygen, creating a severe risk to workers entering these spaces without atmospheric testing and proper confined-space procedures.[13][3][14][11]

- Multiple SDS documents emphasize that wet activated carbon (including granular activated carbon) can absorb and deplete oxygen and that confined entries must be preceded by gas testing and appropriate respiratory protection.[14][13]

- This oxygen depletion hazard is one of the main reasons granular activated carbon systems such as large filters, contactors, or adsorption vessels are treated as permit-required confined spaces in many facilities.[3][11]

Combustible dust and fire risk

Granular activated carbon itself is a carbonaceous material that can form combustible dust clouds if fine particles become suspended in air and encounter an ignition source in a confined or semi-confined environment. While granular activated carbon is typically characterized as having weak dust explosivity (class St1), many SDS documents caution that dust accumulation and dispersion must be controlled to minimize explosion risk.[15][3]

- Typical activated carbon dust data show combustible dust behavior with reported explosion indices in the St1 range, and guidelines recommend housekeeping to prevent dust layers, as well as control of ignition sources in areas where granular activated carbon is transferred or handled.[3][15]

- Some granular activated carbon SDS sheets list flammability or self-heating warnings for large masses, advising storage away from strong oxidizers and strong ignition sources, and recommending that spills be handled in ways that minimize dust clouds.[14][3]

Is granular activated carbon hazardous waste?

Virgin granular activated carbon is usually not considered a hazardous waste, but once granular activated carbon is used to treat contaminated streams, the spent carbon may be classified as hazardous depending on what has been adsorbed. Regulatory frameworks emphasize that spent granular activated carbon must be evaluated for toxicity, ignitability, corrosivity, or reactivity, and may fall under hazardous waste regulations if it carries high levels of hazardous substances.[4][5][7]

- Fact sheets for granular activated carbon stress that “hazardous media” classification is driven by the contaminants captured on the granular activated carbon, not by the carbon itself, and refer users to hazardous waste generator regulations such as EPA Title 40 rules.[5][4]

- Many manufacturers note that spent granular activated carbon can either be regenerated (reactivated) in specialized facilities or disposed of in accordance with local hazardous or non-hazardous waste regulations based on testing results.[7][4]

Typical PPE and safe handling for GAC

Standard safe-handling recommendations for granular activated carbon include minimizing dust, using ventilation, and wearing basic personal protective equipment such as safety glasses, dust masks or respirators when dusty, and work gloves. Because granular activated carbon dust is treated as a low-toxicity nuisance dust, OSHA-style guidance focuses on irritation control, housekeeping, and avoiding ingestion rather than on systemic toxicity.[1][10][12]

- Many SDS documents recommend using NIOSH-approved particulate respirators where granular activated carbon dust levels may exceed general nuisance dust limits or where process conditions create visible dust.[10][1]

- Instructions also highlight the importance of washing after handling granular activated carbon, laundering contaminated clothing, avoiding eating or smoking in work areas, and storing granular activated carbon in closed, labeled containers away from strong oxidizing agents.[12][1]

When granular activated carbon becomes more hazardous

Granular activated carbon may become more hazardous when it is impregnated with reactive chemicals, loaded with toxic contaminants, or exposed to conditions that promote self-heating or reaction with strong oxidizers. For example, certain impregnated granular activated carbon products for gas-phase applications include chemicals that can leach or react, requiring more stringent handling practices and monitoring of any liquid contacting the media.[3][5][10][7]

- Safety data sheets for impregnated and spent granular activated carbon often warn that liquids draining from the media can be hazardous and that both the granular activated carbon and any leachate must be evaluated according to hazardous waste laws.[10][7]

- Some guidance notes that spent granular activated carbon from applications such as radon removal, VOC control, or specific industrial processes may build up radioactive species or toxic organics, requiring careful classification, shielding, or specialized disposal routes.[4][7]

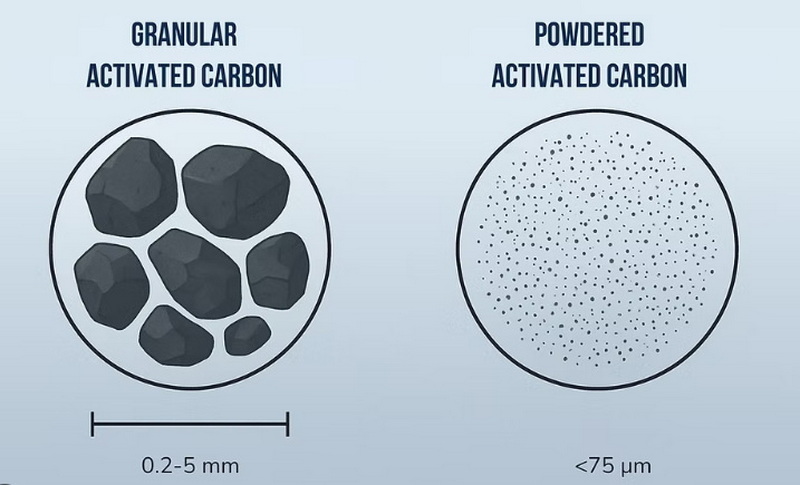

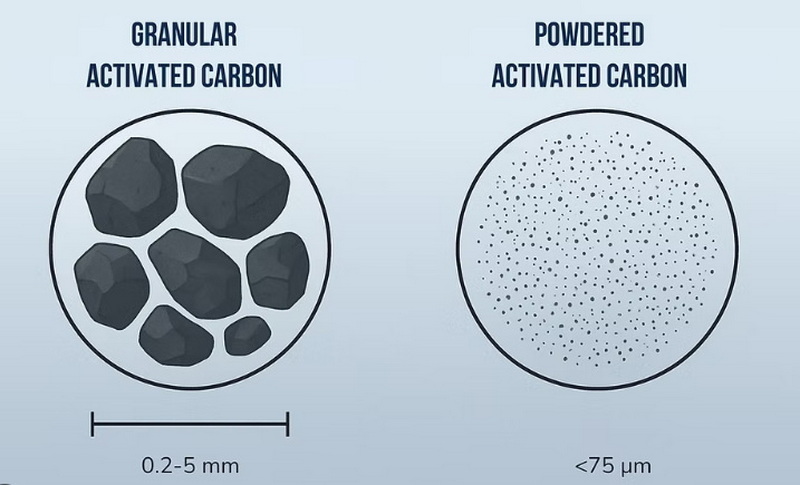

Comparison: GAC vs PAC hazards

Powdered activated carbon (PAC) generally presents higher dust and explosion risk compared with granular activated carbon, although the basic carbon chemistry is similar. Granular activated carbon, by contrast, usually has larger particle size and is handled in fixed beds, which reduces airborne dust formation but does not completely eliminate dust during filling, emptying, or transport.[15][3]

Hazard comparison of granular activated carbon vs powdered activated carbon

| Aspect | Granular activated carbon (GAC) | Powdered activated carbon (PAC) |

| Typical particle size | Larger granules for fixed beds, lower tendency to become airborne.wqa+1 | Very fine powder, easily dispersed as airborne dust.carbotecnia+1 |

| Dust explosion risk | Combustible dust risk, usually weaker due to fewer fine particles.carbotecnia+1 | Higher combustible dust risk; classified as weakly explosive dust (St1).carbotecnia+1 |

| Health irritation (dust) | Dust causes eye and respiratory irritation; nuisance dust limits apply.targetproducts+1 | Similar irritation but more pronounced due to finer dust and higher surface area.laballey+1 |

| Oxygen depletion (wet media) | Wet granular activated carbon can deplete oxygen in confined spaces.sorbtech+1 | Wet powdered activated carbon has the same oxygen depletion hazard.sorbtech+1 |

| Waste classification (spent) | Spent granular activated carbon may be hazardous depending on adsorbed pollutants.wqa+1 | Spent powdered activated carbon is similarly classified based on contaminants.wqa+1 |

Practical risk management for granular activated carbon users

For industrial users, the key to managing granular activated carbon safely is to treat it as a low-toxicity but combustible adsorbent that can irritate via dust, consume oxygen, and become hazardous once loaded with contaminants. Facility risk assessments typically consider dust generation, potential ignition sources, confined-space entries, and waste-stream classification for spent granular activated carbon.[2][4][15]

- Water treatment facilities, industrial plants, and air-purification systems that use granular activated carbon often implement dust extraction, explosion-protection concepts, confined-space permits, and sampling of spent carbon to determine whether it must be handled as hazardous waste.[4][15]

- Many suppliers of granular activated carbon offer technical support to help users choose appropriate grades, design safe handling and regeneration practices, and comply with environmental regulations on spent carbon and off-gas emissions.[5][4]

Conclusion

Granular activated carbon itself is typically not classified as a hazardous chemical, but it has specific, well-documented hazards that must be managed: dust irritation, combustible dust behavior, oxygen depletion in confined spaces, and potential hazardous-waste classification once contaminated. By understanding these granular activated carbon hazards and applying proper engineering controls, PPE, confined-space procedures, and waste-management practices, industries can safely leverage granular activated carbon for water treatment, air and gas purification, food and beverage processing, chemical production, and pharmaceutical applications around the world.[2][15][4]

FAQ About Granular Activated Carbon Hazards

1) Is granular activated carbon toxic to humans?

Granular activated carbon is generally considered low in toxicity and is often described as non-toxic by ingestion or inhalation, although its dust can mechanically irritate the respiratory tract and eyes. Safety data sheets do not typically list granular activated carbon as carcinogenic, and hazard statements focus on irritation, dust control, and confined-space oxygen depletion rather than systemic poisoning.[9][1][10]

2) Can granular activated carbon cause explosions?

Granular activated carbon can contribute to dust explosions if fine particles accumulate, become airborne in sufficient concentration, and encounter an ignition source in an enclosed or semi-enclosed area. However, granular activated carbon dust is generally classified as weakly explosive (class St1), so proper housekeeping, dust collection, and ignition control significantly reduce explosion risk.[3][15]

3) Is wet granular activated carbon dangerous?

Wet granular activated carbon is dangerous in confined spaces because it can remove oxygen from air, potentially lowering oxygen levels to the point where workers are at serious risk of asphyxiation. For this reason, guidance for granular activated carbon filters and vessels stresses oxygen testing, ventilation, and full confined-space entry procedures before any worker enters equipment containing wet granular activated carbon.[13][11][14][3]

4) Is spent granular activated carbon always hazardous waste?

Spent granular activated carbon is not automatically hazardous but may be classified as hazardous waste depending on the type and concentration of contaminants adsorbed, such as toxic organics, heavy metals, or radionuclides. Regulations typically require testing or process knowledge to determine whether spent granular activated carbon must be handled as hazardous waste, and many operators use regeneration services or specialized disposal routes for such media.[7][5][4]

5) What PPE is recommended when handling granular activated carbon?

When handling granular activated carbon, standard recommendations include safety glasses or goggles, work gloves, and protective clothing, with dust masks or respirators used where airborne dust levels may be elevated. In addition, workers should have access to eye-wash facilities, avoid eating or smoking in work areas, and follow site procedures for confined-space entry when working around large granular activated carbon vessels or filters.[1][12][10]

Citations:

[1](https://www.targetproducts.com/PDFs/SDS-Granular-Activated-Carbon.pdf)

[2](https://consult.environment-agency.gov.uk/psc/tw7-7lp-thames-water-utilities-limited-v006/supporting_documents/10.%20Granular%20Activated%20Carbon%20SDS%20V005%20%20191223.pdf)

[3](https://www.carbotecnia.info/PDF/MSDS/MSDS_micro_EN.pdf)

[4](https://wqa.org/wp-content/uploads/2022/09/2016_GAC.pdf)

[5](https://norit.com/hubfs/S-GAC-Europe-EN.pdf?hsLang=en)

[6](https://www.ameriwater.com/wp-content/uploads/2018/08/SDS_Carbon_12x40.pdf)

[7](https://clarimex.com/hojas/HDS-03-I%20-%20Physical%20activation%20V3.pdf)

[8](https://shop.chemsupply.com.au/documents/25KND8BM.pdf)

[9](https://norit.com/hubfs/S-GAC-USA&Canada-EN.pdf?hsLang=en)

[10](https://media.laballey.com/docbuilder/activated-carbon-charcoal-granular-food-grade-kosher-safety-data-sheet-672a69c265461.pdf)

[11](https://www.arq.com/wp-content/uploads/2024/06/arq-remediation-series-fluxsorb.pdf)

[12](https://cglimited.com.au/wp-content/uploads/2018/07/NAQ-ACP-Pellets-SDS.pdf)

[13](https://www.sorbtech.com/msds/SDS%20Activated%20Carbon(9-12-22).pdf)

[14](https://labelsds.com/images/user_uploads/Activated%20Carbon%20Hydrodarco%20B%20SDS%205-13-15.pdf)

[15](https://generalcarbon.com/activated-carbon/activated-carbon-msds/)

[16](https://mcpur.com/wp-content/uploads/2021/02/SDS_Carbon_Coal_ME50097.pdf)

[17](https://www.justrite.com/media/catalogs/SDS-Granular-Activated-Carbon.pdf)

[18](https://www.lobachemie.com/lab-chemical-msds/MSDS-CHARCOAL-ACTIVATED-GRANULAR-CASNO-7440-44-02693-EN.aspx)

[19](https://eadn-wc03-12732172.nxedge.io/wp-content/uploads/2021/06/SDS-AF-xx-1046-BB.pdf)