Content Menu

● What Reactivation Really Means

● Why Reactivate Granular Activated Carbon

● Industrial Thermal Reactivation Process

● Optimal Conditions for Reactivating GAC

● Chemical and Solvent‑Based Regeneration

● Limited “Home” Reactivation vs. True Reactivation

● Safety Considerations for Handling Spent GAC

● Environmental Benefits of Reactivating GAC

● Practical Tips for Plant Operators Using GAC

● Where Reactivated GAC Is Commonly Used

● Reactivated vs. Virgin GAC (Key Differences)

● Conclusion

● FAQ About Reactivating Granular Activated Carbon

>> 1. Can I reactivate granular activated carbon at home?

>> 2. How many times can granular activated carbon be reactivated?

>> 3. Is reactivated granular activated carbon safe for drinking water?

>> 4. What is the difference between regeneration and reactivation of granular activated carbon?

>> 5. What should be considered before sending granular activated carbon for reactivation?

● Citations:

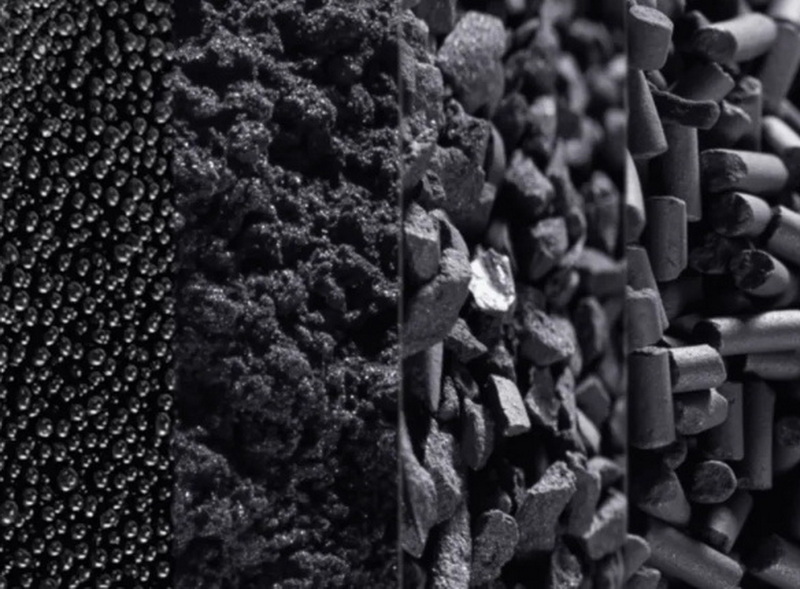

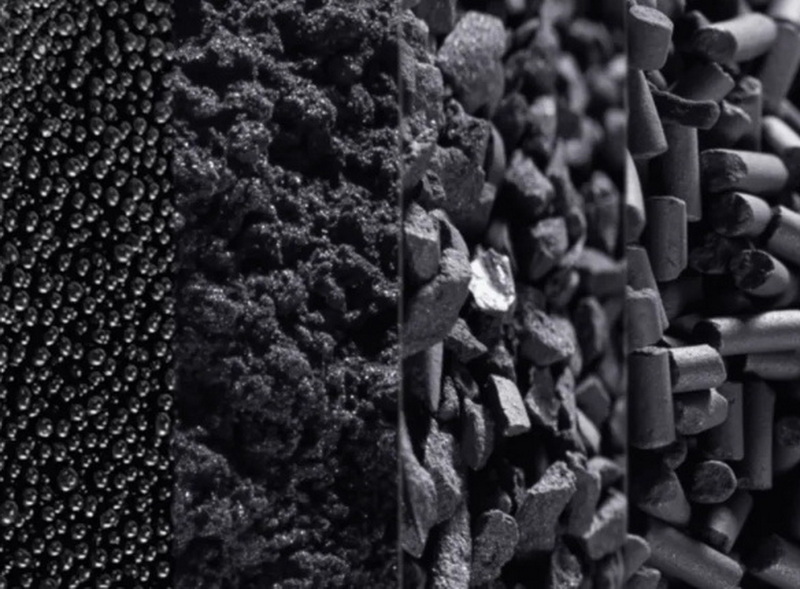

Granular activated carbon (GAC) is widely used in water treatment, air and gas purification, food and beverage, chemicals, and pharmaceuticals because of its high surface area and well‑developed pore structure. Over time, granular activated carbon becomes saturated with contaminants and must be replaced or reactivated to restore adsorption capacity. Reactivating granular activated carbon correctly can significantly reduce disposal costs, lower CO₂ footprint, and support more sustainable industrial operations.[5][6][4][7][8][9]

What Reactivation Really Means

Reactivation of granular activated carbon is a process that removes adsorbed pollutants and reopens blocked pores so that the carbon can regain much of its original adsorption capacity. In practice, this usually involves heating spent granular activated carbon to high temperatures in an oxygen‑limited atmosphere, sometimes with steam or other gases.[6][4][1][5]

Industrial thermal reactivation of granular activated carbon often takes place in rotary kilns or multi‑hearth furnaces at around 600–950 °C, depending on the type of carbon and contaminants. During this process, the adsorbed organics are volatilized or pyrolyzed, then oxidized in separate afterburners and treated by scrubbers before emission.[10][4][11][6]

Why Reactivate Granular Activated Carbon

Reactivating granular activated carbon instead of sending it to landfill or incineration offers several technical and economic benefits. Reactivated granular activated carbon often costs significantly less than virgin carbon while still meeting performance targets for many applications.[4][9][5][6]

Key advantages of granular activated carbon reactivation include:[8][6]

- Lower total cost of ownership for water, air, and gas purification systems using granular activated carbon.

- Significant reduction in solid waste volume and long‑term disposal liabilities for spent granular activated carbon.

- Smaller carbon footprint compared with producing and transporting new granular activated carbon.

- Possibility of closed‑loop service agreements where spent granular activated carbon is collected, reactivated, and returned.

Industrial Thermal Reactivation Process

In professional facilities, granular activated carbon reactivation follows a controlled sequence designed for efficiency, safety, and environmental compliance. The exact parameters depend on the feedstock (coal‑based, coconut‑based, wood‑based), particle size, and loading of contaminants in the granular activated carbon.[12][1][4][8]

Typical steps to reactivate granular activated carbon thermally are:[1][6]

1. Collection and classification

Spent granular activated carbon is collected from filters, adsorbers, or columns and transported—often still wet—to a reactivation plant. The granular activated carbon is inspected and segregated by source and contamination class (e.g., potable water, industrial organics, PFAS) to meet regulatory and quality standards.[7][6][10][1]

2. Drying stage

The wet granular activated carbon is first dried at moderate temperatures to remove free water and prevent sudden steam explosions inside the furnace. Proper drying improves heat transfer and prepares the granular activated carbon for subsequent pyrolysis and activation.[13][3]

3. Pyrolysis of adsorbed organics

As the granular activated carbon temperature increases, organic contaminants decompose and volatilize in an oxygen‑limited environment. The gases generated are routed to high‑temperature afterburners and gas‑cleaning systems to destroy hazardous compounds before release.[11][5][6][4]

4. Steam activation step

Steam is injected at high temperature (often 750–900 °C) to gasify char and reopen the micro‑ and mesopores of the granular activated carbon. At these temperatures, steam reacts with carbon residues, restoring adsorption sites and regenerating the internal surface area.[2][14][4][1]

5. Cooling and handling

Reactivated granular activated carbon is cooled under controlled conditions to prevent oxidation and dust ignition. After cooling, the granular activated carbon is screened, tested for properties such as iodine number, hardness, and residual contaminants, then packaged for reuse.[3][9][6][4]

Optimal Conditions for Reactivating GAC

The performance of reactivated granular activated carbon depends strongly on temperature, residence time, and atmosphere in the furnace. Too low a temperature leaves contaminants in the pores, while too high a temperature can collapse the pore structure and permanently reduce capacity.[14][2][12]

- Many industrial processes reactivate granular activated carbon at 600–900 °C, with common operating windows around 750–850 °C for energy‑efficient regeneration.[14][4]

- Residence times of about 30–45 minutes at peak temperature are typical to balance regeneration efficiency and carbon loss.[9][14]

- A low‑oxygen, often steam‑rich atmosphere is maintained to minimize combustion of the granular activated carbon itself while promoting desorption and gasification of contaminants.[6][1]

Chemical and Solvent‑Based Regeneration

Besides thermal methods, some technologies use solvents or electrochemical methods to regenerate granular activated carbon for specific applications. These approaches can be attractive where thermal reactivation is difficult or where specific contaminants such as PFAS require tailored strategies.[15][16][13]

- Solvent‑based regeneration circulates a regenerant solution through a granular activated carbon bed to dissolve or displace adsorbed compounds, followed by distillation and treatment of the regenerant.[15]

- Electrochemical regeneration places granular activated carbon between electrodes in an electrolyte and applies a DC field, promoting desorption and oxidative degradation of pollutants on the carbon surface.[13]

Such methods can reduce energy consumption and enable on‑site regeneration of granular activated carbon, but require careful chemical management and system design.[13][15]

Limited “Home” Reactivation vs. True Reactivation

True reactivation of granular activated carbon, as used in industrial water and gas treatment, demands temperatures near 900 °C, controlled atmospheres, and emissions control, which are not realistic for home users. Lower‑temperature treatment such as baking spent granular activated carbon in a domestic oven does not fully restore the original pore structure or capacity.[17][3][1]

Some sources mention that granular activated carbon contaminated with low‑boiling impurities can be partially refreshed with low‑pressure steam or moderate heating (around 200–400 °F) to remove loosely bound species. However, this is best regarded as partial restoration of granular activated carbon performance, not equivalent to professional thermal reactivation.[3][17]

Safety Considerations for Handling Spent GAC

Spent granular activated carbon may contain concentrated hazardous substances, and reactivation conditions can transform contaminants into more toxic intermediates at high temperatures. Therefore, any attempt to reactivate granular activated carbon must consider safety, health, and environmental controls.[17][9]

Key safety measures when handling or preparing granular activated carbon for reactivation include:[18][3]

- Using appropriate dust protection (respirators, goggles, local extraction) when transferring dry granular activated carbon.

- Avoiding entry into confined spaces with large volumes of granular activated carbon without checking oxygen content and toxic gases.

- Recognizing that wet granular activated carbon can deplete oxygen in enclosed spaces, posing asphyxiation risks.

- Ensuring that thermal reactivation of granular activated carbon occurs only in engineered systems with proper off‑gas treatment.

Environmental Benefits of Reactivating GAC

From a sustainability perspective, reactivating granular activated carbon supports circular economy strategies in water treatment, industrial emissions control, and product purification. The environmental footprint of reactivated granular activated carbon is generally lower than that of producing virgin carbon, thanks to reduced raw material consumption and energy use per unit of adsorption capacity.[16][9][6]

Many leading suppliers operate regional reactivation plants so that spent granular activated carbon can be transported, reprocessed, and returned, minimizing transportation distances and waste. In advanced applications such as PFAS removal, carefully controlled thermal reactivation or specialized regeneration technologies ensure that contaminants are destroyed or isolated rather than released back to the environment.[10][7][8][6]

Practical Tips for Plant Operators Using GAC

For operators running filters or adsorbers with granular activated carbon, effective reactivation starts with good monitoring and maintenance practices. Proper operation extends the service life of granular activated carbon and ensures that reactivation, when performed, delivers consistent performance.[5][3]

Practical tips for managing granular activated carbon reactivation include:[4][5]

- Track breakthrough curves, pressure drop, and effluent quality to determine optimal change‑out points for granular activated carbon.

- Keep detailed records of feed water or gas quality so reactivation partners can select appropriate furnace conditions.

- Segregate granular activated carbon streams from food, potable water, and industrial processes to maintain compliance and product quality.

- Work with a qualified reactivation service provider that can test reactivated granular activated carbon and certify its suitability for your application.

Where Reactivated GAC Is Commonly Used

Reactivated granular activated carbon can be reused in many applications, sometimes in the same duty and sometimes in less critical stages. The decision depends on regulatory requirements, risk tolerance, and performance tests on the specific grade of reactivated granular activated carbon.[8][6][4]

Common uses include:[7][6]

- Industrial wastewater polishing and organic removal with reactivated granular activated carbon.

- Vapor phase treatment for VOC control using reactivated granular activated carbon.

- Certain municipal and industrial water applications where regulations permit reactivated granular activated carbon.

- Staged systems where virgin granular activated carbon is used in the final polishing stage and reactivated granular activated carbon in upstream stages.

Reactivated vs. Virgin GAC (Key Differences)

| Aspect | Virgin granular activated carbon | Reactivated granular activated carbon |

| Source material | Fresh raw materials (e.g. coal, coconut shell)generalcarbon | Previously used granular activated carbon from field applicationscalgoncarbon |

| Production / processing | Full activation cycle in new kilnsgeneralcarbon | High‑temperature reactivation in specialized furnacesnorit+1 |

| Adsorption capacity | Baseline capacity of the original productgeneralcarbon | Typically slightly lower but still suitable for many dutiespeltonenv+1 |

| Cost per unit | Higher total costpeltonenv | Generally lower than virgin granular activated carbonpeltonenv+1 |

| Environmental footprint | Higher resource and energy demandcalgoncarbon | Lower CO₂ footprint and less solid wastecalgoncarbon+1 |

| Regulatory limitations | Often allowed for sensitive uses like drinking waterwcponline | Sometimes restricted for specific high‑purity uses; allowed for many industrial processes |

Conclusion

Reactivating granular activated carbon is an essential step in the lifecycle of modern water, air, and process purification systems, allowing operators to recover value from spent media and reduce waste. For true reactivation, granular activated carbon must be processed at high temperature in controlled furnaces with robust emissions treatment, which is why industrial users normally rely on professional reactivation services rather than attempting reactivation on site or at home. By choosing appropriate reactivation partners, optimizing operating conditions, and understanding where reactivated granular activated carbon best fits, you can combine strong performance with improved sustainability and cost control.[9][1][5][6][8]

FAQ About Reactivating Granular Activated Carbon

1. Can I reactivate granular activated carbon at home?

True reactivation of granular activated carbon requires temperatures close to 900 °C, controlled atmospheres, and off‑gas treatment that home equipment cannot provide. Household ovens or simple heating can at best remove some volatile substances from granular activated carbon but will not fully restore adsorption capacity or pore structure.[1][3][17]

2. How many times can granular activated carbon be reactivated?

The number of successful reactivation cycles depends on the raw material, particle size, and mechanical strength of the granular activated carbon. Each cycle causes some carbon loss and potential structural change, but high‑quality granular activated carbon can often be reactivated multiple times while still meeting performance requirements for many industrial applications.[5][4][9]

3. Is reactivated granular activated carbon safe for drinking water?

In some regions, carefully controlled reactivated granular activated carbon is used in potable water treatment, but regulations vary and may restrict reactivated granular activated carbon in certain critical positions. Utilities typically rely on stringent quality testing and sometimes reserve virgin granular activated carbon for final polishing stages, using reactivated granular activated carbon in upstream steps.[6][3][4][7]

4. What is the difference between regeneration and reactivation of granular activated carbon?

In practice, “regeneration” often refers to restoring granular activated carbon using chemical or low‑temperature methods on site, while “reactivation” typically means full high‑temperature treatment in specialized furnaces. Regeneration may partially recover granular activated carbon capacity, whereas thermal reactivation aims to achieve performance close to the original product by completely reopening the pore structure.[2][4][13]

5. What should be considered before sending granular activated carbon for reactivation?

Before sending granular activated carbon for reactivation, operators should document the process conditions, type of contaminants, and any hazardous substances that may be present. This information allows the reactivation facility to select suitable furnace conditions, ensure environmental compliance, and determine whether reactivation of the specific granular activated carbon stream is technically and legally feasible.[11][10][8][6]

Citations:

[1](https://norit.com/reactivation)

[2](https://www.carbotecnia.info/en/learning-center/activated-carbon-theory/activated-carbon-reactivation/)

[3](https://wcponline.com/2005/06/22/care-handling-activated-carbon/)

[4](https://generalcarbon.com/reactivated-carbon/)

[5](https://www.peltonenv.com/blog/carbon-reactivation-lifecycle-of-granular-activated-carbon-gac)

[6](https://www.calgoncarbon.com/reactivation-services/)

[7](https://serdp-estcp.mil/projects/details/4530d199-9371-4795-af3d-0b2bc688ee30)

[8](https://www.chemviron.eu/solutions/activated-carbon-reactivation/)

[9](https://pmc.ncbi.nlm.nih.gov/articles/PMC7180969/)

[10](https://www.chemviron.eu/solutions/pfas-removal/reactivation-pfas/)

[11](https://19january2021snapshot.epa.gov/sites/static/files/documents/airemissions.pdf)

[12](https://www.sciencedirect.com/science/article/abs/pii/S004313540600515X)

[13](https://gasificationplant.com/biomass-energy/activated-carbon-regeneration-methods/)

[14](https://www.carbonyihang.com/Eco-Friendly-Reactivation-Tips-for-Used-Granular-Activated-Carbon-in-Plants)

[15](https://www.battelle.org/markets/environment/pfas-and-emerging-chemicals/pfas-destruction-and-remediation/granular-activated-carbon-regeneration-technology)

[16](https://revive-environmental.com/what-is-granular-activated-carbon-regeneration-and-why-it-matters-for-pfas-removal/)

[17](https://charcoalhouse.com/blog/can-i-reactivate-my-charcoal/)

[18](https://www.targetproducts.com/PDFs/SDS-Granular-Activated-Carbon.pdf)

[19](https://www.reddit.com/r/AirPurifiers/comments/1f7b6wn/regenerate_activated_charcoal/)

[20](https://www.reddit.com/r/Survival/comments/thwg5a/what_are_the_safety_considerations_to_activating/)