Content Menu

● What Is Powdered Activated Carbon?

>> Typical Properties of Powdered Activated Carbon

● Main Applications of Powdered Activated Carbon

● Powdered vs. Granular Activated Carbon

>> Key Differences Between PAC and GAC

● Raw Materials for Powdered Activated Carbon

● Overview of the Production Process

● Step‑by‑Step: How to Make Powdered Activated Carbon (Chemical Route)

>> 1. Raw Material Preparation

>> 2. Phosphoric Acid Impregnation

>> 3. Carbonization and Activation

>> 4. Acid Recovery and Exhaust Treatment

>> 5. Washing and Neutralization

>> 6. Dewatering and Drying

>> 7. Grinding and Sieving to Powdered Form

>> 8. Final Packaging and Quality Control

● Physical Activation Route to Powdered Activated Carbon

● How Powdered Activated Carbon Works

● Using Powdered Activated Carbon in Industrial Applications

● Conclusion

● FAQ About Powdered Activated Carbon

>> 1. What is powdered activated carbon?

>> 2. How is powdered activated carbon different from granular activated carbon?

>> 3. What are the main steps in making powdered activated carbon?

>> 4. Where is powdered activated carbon used?

>> 5. How do you choose the right powdered activated carbon grade?

● Citations:

Powdered activated carbon is made by carbonizing a carbon‑rich raw material and then activating it at high temperature to create a highly porous fine powder with strong adsorption capacity. It is then washed, dried, milled, and sieved to achieve the desired particle size distribution for water, air, and industrial purification applications.[1][2][3][4]

What Is Powdered Activated Carbon?

Powdered activated carbon (PAC) is a very fine form of activated carbon, typically with particle sizes below 0.1–0.18 mm and at least 90% passing about 100–200 μm mesh depending on the standard. This extremely small particle size provides a very large external surface area and short diffusion paths, which leads to rapid adsorption of contaminants from liquids and gases.[5][6][7]

PAC is usually produced from organic raw materials with high carbon content such as wood, sawdust, lignite, or coal, which are converted into a porous, high‑surface‑area material through controlled thermal and/or chemical processes. Typical internal surface areas for powdered activated carbon are on the order of hundreds to about 900 m²/g or more, giving it exceptional capacity to remove color, odor, and trace pollutants.[8][6][7][1]

Typical Properties of Powdered Activated Carbon

- Particle size: majority < 0.18 mm, with effective sizes often 20–50 μm.[6][7]

- Bulk density: roughly 250–600 kg/m³ depending on raw material and activation method.[3][6]

- Iodine number: commonly around 800–1500 mg/g, indicating strong micropore adsorption capacity.[3][6]

- Moisture and ash: moisture typically 3–8 wt% and ash 3–15 wt%, depending on raw material and washing level.[6][3]

Main Applications of Powdered Activated Carbon

Powdered activated carbon is widely used where fast, flexible treatment is needed rather than permanent fixed‑bed systems. Because PAC can be dosed directly into liquids or gases and then removed, it is ideal for batch or emergency treatment as well as polishing processes.[9][10][11][5]

Key applications of powdered activated carbon include:

- Municipal and industrial drinking‑water treatment for removal of pesticides, pharmaceuticals, natural organic matter, and taste/odor compounds.[10][11]

- Wastewater treatment to reduce color, COD, trace organics, and toxic micro‑pollutants.[12][11]

- Air and gas purification for VOCs, odors, and specific gaseous contaminants in industrial exhaust and process gases.[13][14]

- Food and beverage decolorization and purification, such as sugar, edible oils, beverages, and additives.[14][12]

- Chemical and pharmaceutical processing for purification of intermediates, solvents, and finished products where high purity is critical.[13][14]

Powdered vs. Granular Activated Carbon

When deciding whether to produce or use powdered activated carbon or granular activated carbon (GAC), it helps to compare their key characteristics. Powdered activated carbon is generally chosen for rapid, one‑time or short‑term treatments, while GAC is preferred for continuous filtration systems.[15][9][10]

Key Differences Between PAC and GAC

| Feature | Powdered Activated Carbon (PAC) | Granular Activated Carbon (GAC) |

| Typical particle size | < 0.18 mm; many particles 20–50 μmguidelines.nhmrc+1 | About 0.5–4 mm granulesbygen+1 |

| Adsorption speed | Very fast due to short diffusion pathssciencedirect+1 | Slower, diffusion‑limited in larger particlesbygen |

| Usage mode | Dosed into liquid/gas, then separatedsciencedirect+1 | Packed beds or fixed filtersbygen+1 |

| Typical service pattern | Single‑use or short‑term dosingallcarbontech | Regenerable, long‑term operationbygen+1 |

| Best suited applications | Shock loads, seasonal taste/odor, polishingallcarbontech+1 | Continuous municipal water or air systemsbygen+1 |

Raw Materials for Powdered Activated Carbon

To make powdered activated carbon, a carbon‑rich raw material is selected based on availability, cost, and desired pore structure. Common choices include wood or sawdust for more meso‑ and macroporous PAC, and coal or lignite for stronger, mechanically robust carbons with different pore distributions.[4][7][1]

Wood‑based powdered activated carbon is frequently produced by chemical activation with phosphoric acid, starting from screened and dried sawdust. Coal‑based powdered activated carbon usually follows a physical activation route, with carbonization and high‑temperature steam or carbon‑dioxide activation, followed by grinding into fine powder.[16][2][1][4]

Typical raw materials for powdered activated carbon include:

- Wood and sawdust: good for high‑activity PAC for liquids and food‑grade applications.[1][16]

- Lignite or bituminous coal: used for robust PAC with tailored pore structure for water and flue‑gas treatment.[2][7]

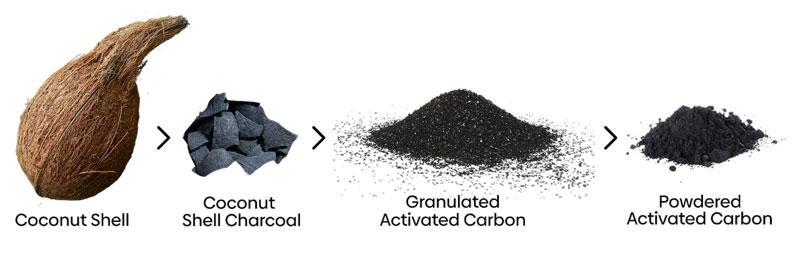

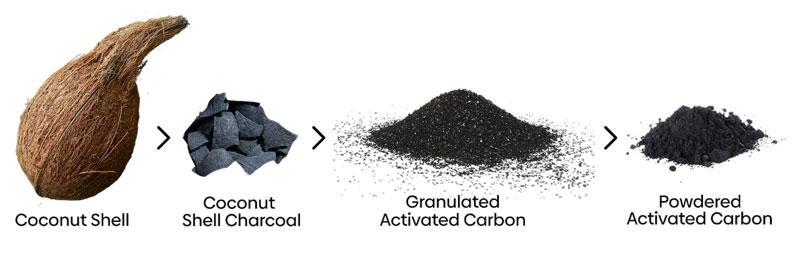

- Other biomass (coconut shells, agricultural residues): sometimes used where local supply and sustainability are priorities.[4][14]

Overview of the Production Process

The production of powdered activated carbon generally follows two main stages: carbonization and activation, followed by post‑treatment steps like washing, drying, grinding, and packaging. Depending on whether physical or chemical activation is used, the detailed steps and temperatures vary, but the core goal is to create a highly porous structure and then bring it to the desired fine powder form.[2][1][4]

For chemical activation of wood‑based powdered activated carbon, phosphoric acid impregnation, lower‑temperature carbonization/activation, and acid recovery are key elements. For coal‑based powdered activated carbon, higher‑temperature carbonization and steam or carbon‑dioxide activation in rotary kilns or furnaces are typical.[16][1][2][4]

Step‑by‑Step: How to Make Powdered Activated Carbon (Chemical Route)

Below is a typical wood‑ or sawdust‑based phosphoric‑acid activation process for powdered activated carbon, which is widely used for high‑activity PAC for liquid‑phase applications.[1][16]

1. Raw Material Preparation

Sawdust or other wood feedstock is first screened to remove oversized or foreign particles and to obtain a consistent particle size distribution. The material is then dried to a suitable moisture content so that it can be uniformly impregnated with phosphoric acid and processed in subsequent thermal steps.[4][1]

In industrial powdered activated carbon production, ensuring uniform particle size and moisture reduces variation in pore structure and yield. Stable feed preparation helps achieve consistent iodine number, bulk density, and adsorption performance in the finished powdered activated carbon.[17][3][1]

2. Phosphoric Acid Impregnation

A phosphoric acid solution, typically with a concentration in the range of about 40–60%, is prepared as the chemical activating agent. The dried sawdust is mixed or immersed (impregnated) in this solution, usually for an extended period such as 12–24 hours to ensure thorough penetration.[16][1]

The ratio of phosphoric acid to raw material strongly influences pore development and yield, so it is adjusted to meet specific powdered activated carbon specifications. After impregnation, the mixture is drained and may be mechanically dewatered before entering the carbonization and activation stages.[3][1][4]

3. Carbonization and Activation

The impregnated material is heated in a furnace or kiln under controlled conditions, where carbonization and activation occur, often in an overlapping temperature range around 400–600 °C. During carbonization, non‑carbon elements are driven off as volatile compounds, and a basic carbon skeleton with initial pores is formed.[2][1][4]

In the presence of phosphoric acid, dehydration and crosslinking reactions help open and stabilize a highly porous structure within the carbon. Process parameters such as heating rate, peak temperature, and residence time (for example 2–3 hours) are carefully controlled to tailor the pore size distribution and adsorption capacity of the resulting powdered activated carbon.[1][16][4]

4. Acid Recovery and Exhaust Treatment

Because phosphoric acid is both a process cost and an environmental concern, exhaust gases and condensates are often treated to recover usable acid. Specialized exhaust gas treatment systems can capture phosphoric and sometimes sulfuric acid from the flue gas, reducing emissions and improving sustainability of powdered activated carbon manufacturing.[14][1]

Recycled acid can be re‑used in impregnation after appropriate treatment and concentration adjustment, which lowers operating cost per ton of powdered activated carbon and reduces waste. Effective gas and liquid handling also helps the plant comply with air and water discharge regulations in target export markets.[17][6][14][1]

5. Washing and Neutralization

After activation, the carbonized/activated solids contain residual phosphoric acid and soluble inorganic impurities that must be washed out. The material is typically treated with water, sometimes with controlled pH steps, to remove acid and dissolved salts, while preserving pore structure.[8][1]

Multiple rinsing stages are used until conductivity or pH targets are met, ensuring that the final powdered activated carbon meets ash content, pH, and extractable impurity specifications. Proper washing is especially important for food‑grade and pharmaceutical‑grade powdered activated carbon used in sensitive applications.[6][14][3]

6. Dewatering and Drying

Once washed, the wet carbon is mechanically dewatered, often by centrifugation, to remove as much free water as practical before drying. Centrifugal dewatering reduces energy consumption in the dryers and shortens drying time for powdered activated carbon production lines.[2][1]

The dewatered material is then dried in suitable dryers to bring the moisture content down to the specified range, often a few percent by weight. Controlled drying avoids overheating, which could damage pore structure, and ensures stable handling, packaging, and storage for the powdered activated carbon.[3][6][1]

7. Grinding and Sieving to Powdered Form

After drying, the activated carbon is still in granular or irregular chip form and must be ground to the required fine powder size. Raymond mills or similar fine grinding mills are commonly used to produce powdered activated carbon with most particles below 0.18 mm.[7][2]

The ground product is then sieved and classified so that it meets particle size specifications, such as a minimum of 90–95% passing specific mesh sizes like 100 or 200 μm. Consistent fine particle size is crucial to ensure that powdered activated carbon disperses well in water or process liquids and delivers fast adsorption kinetics.[5][7][10][6]

8. Final Packaging and Quality Control

Finished powdered activated carbon is packaged in moisture‑resistant bags, bulk bags, or containers, protecting it from humidity and contamination during transport and storage. Before shipment, the material is tested for key parameters such as iodine number, methylene blue or molasses value, pH, bulk density, ash content, moisture, and particle size distribution.[18][6][1][3]

These tests confirm that each batch of powdered activated carbon meets the technical requirements for its intended application, for example drinking‑water treatment, food‑grade use, or industrial gas purification. Trace‑element and extractables testing may also be performed for sensitive markets such as pharmaceuticals and high‑purity chemicals.[9][13][14][6]

Physical Activation Route to Powdered Activated Carbon

For coal‑based powdered activated carbon, a common alternative is physical activation, which separates carbonization and activation and uses steam or carbon dioxide as the activating agent. In this route, raw coal or other carbonaceous material is first carbonized at about 350–600 °C to form a char with preliminary pore structure.[4][2]

The char is then heated to higher temperatures, often 800–1000 °C, while steam or carbon dioxide flows through the reactor, selectively gasifying carbon at pore surfaces and creating extensive porosity. After cooling and any required washing, the activated product is dried and then milled to produce powdered activated carbon following similar grinding and classification steps as in the chemical route.[7][1][2][4]

Physical activation typically produces very thermally stable carbons suited to applications such as flue‑gas and industrial gas treatment, as well as certain water‑treatment uses. Choice between physical and chemical processes for powdered activated carbon depends on raw material, cost, environmental factors, and target performance.[19][13][1][4]

How Powdered Activated Carbon Works

Powdered activated carbon works through adsorption, where molecules from a fluid phase adhere to the vast internal surface within the carbon's micro‑ and mesopores. The combination of high internal surface area, appropriate pore size distribution, and functional surface chemistry enables removal of a wide range of organic compounds and some inorganic species.[10][8][6]

In water treatment, powdered activated carbon rapidly adsorbs pesticides, natural organic matter, taste‑ and odor‑forming compounds, and many synthetic organic chemicals. In air and gas treatment, powdered activated carbon can capture VOCs, odorous compounds, and certain hazardous gases, sometimes with additional chemical impregnation to enhance selectivity.[11][13][10][14]

Using Powdered Activated Carbon in Industrial Applications

Because powdered activated carbon is a fine powder, it is usually applied as a slurry or by direct dosing into process streams, followed by separation. Typical methods include injection into mixing basins in water plants, addition to contact tanks in wastewater treatment, or dosing into gas streams with subsequent filtration or cyclones.[12][11][5]

Dosing rates of powdered activated carbon depend on contaminant type and concentration, contact time, and required effluent quality, and are often optimized through jar testing or pilot trials. After contact, PAC is removed via sedimentation, filtration, or other solid‑liquid separation methods, and spent powdered activated carbon is usually disposed or, in some cases, thermally treated or regenerated.[11][5][10][12]

Conclusion

Powdered activated carbon is produced by carefully selecting a carbon‑rich raw material, then applying carbonization, activation, and fine grinding to create a highly porous, fast‑acting adsorbent in powder form. Through controlled process parameters and thorough washing, drying, and classification, manufacturers can supply powdered activated carbon tailored for demanding applications such as drinking‑water treatment, air and gas purification, food and beverage processing, chemical production, and pharmaceuticals.[6][1][4]

FAQ About Powdered Activated Carbon

1. What is powdered activated carbon?

Powdered activated carbon is a finely ground, highly porous form of activated carbon with very small particle size, usually less than about 0.18 mm, designed for rapid adsorption from liquids and gases. Its large surface area and fine particles make powdered activated carbon ideal for short‑contact‑time applications like water treatment and batch purification processes.[5][9][7][6]

2. How is powdered activated carbon different from granular activated carbon?

Powdered activated carbon consists of fine particles that are dosed into a fluid and later separated, while granular activated carbon is used in fixed filter beds. PAC provides faster adsorption and is typically single‑use, whereas GAC is slower but can often be thermally regenerated for long‑term continuous service.[15][10][5]

3. What are the main steps in making powdered activated carbon?

The main steps to produce powdered activated carbon are raw material preparation, carbonization, activation (chemical or physical), washing, drying, grinding to fine powder, and final packaging. Throughout these steps, process control is used to achieve target properties such as iodine number, bulk density, moisture, ash content, and particle size distribution for the powdered activated carbon.[1][2][3][6]

4. Where is powdered activated carbon used?

Powdered activated carbon is widely used in municipal and industrial water treatment, wastewater plants, air and gas purification, and purification of food, beverages, chemicals, and pharmaceuticals. In these applications, powdered activated carbon helps remove organic contaminants, color, off‑flavors, odors, and trace pollutants to meet strict quality and regulatory standards.[13][10][14][11]

5. How do you choose the right powdered activated carbon grade?

Choosing the right powdered activated carbon grade involves considering iodine number or other adsorption indices, particle size, bulk density, ash and moisture levels, pH, and any regulatory certifications needed. For example, drinking‑water and food applications may require specific standards and low extractables, while gas‑phase or industrial uses may prioritize particular pore structures or chemical impregnation in the powdered activated carbon.[9][17][3][6]

Citations:

[1](https://heycarbons.com/manufacture-of-activated-carbon/)

[2](https://rotarykilnfactory.com/how-to-make-coal-based-activated-carbon/)

[3](https://medaad.com/powder-activated-carbon/)

[4](https://feeco.com/introduction-to-activated-carbon/)

[5](https://www.sciencedirect.com/topics/engineering/powdered-activated-carbon)

[6](https://guidelines.nhmrc.gov.au/australian-drinking-water-guidelines/part-5/treatment-chemicals/carbon-powdered-activated)

[7](https://mjhcarbons.com/powdered-activated-carbon-gac.html)

[8](https://www.carbofull.com.sg/uploads/soft/191109/1-191109195519.pdf)

[9](https://www.carbonactivatedeurope.com/activated-carbon/)

[10](https://allcarbontech.com/powder-activated-carbon/)

[11](https://www.huameicarbon.com/powdered-activated-carbon-treatment-principles-applications-and-future-perspectives/)

[12](https://www.sorbotech.uk/115,powdered_activated_carbon)

[13](https://sodimate-inc.com/activated-carbon-types-applications-advantages/)

[14](https://www.carbotecnia.info/en/learning-center/activated-carbon-applications/activated-carbon-applications/)

[15](https://www.bygen.com.au/post/granular-vs-powdered-activated-carbon-which-one-is-right-for-your-application)

[16](https://carbons.ir/en/powdered-activated-carbon-2/)

[17](https://www.servochem.com/products/powdered-activated-carbon/)

[18](https://www.calgoncarbon.com/powdered-activated-carbon/)

[19](https://www.calgoncarbon.com/gas-processing/)

[20](https://jamescumming.com.au/articles/the-production-process-of-powdered-activated-carbon/)