Content Menu

● What Is Activated Carbon

● Raw Materials For Activated Carbon

● Overview Of The Activated Carbon Manufacturing Process

● Step 1: Carbonization

● Step 2: Activation – Physical vs Chemical

>> Physical Activation Of Activated Carbon

>> Chemical Activation Of Activated Carbon

● Step 3: Washing And Drying

● Step 4: Crushing, Sizing, And Forming

● Quality Control In Activated Carbon Manufacturing

● Types Of Activated Carbon By Form And Application

● Environmental And Regeneration Aspects

● Conclusion

● FAQs About How Activated Carbon Is Manufactured

>> (1) How is activated carbon different from regular charcoal?

>> (2) Which activation method is better: physical or chemical?

>> (3) Why are different raw materials used to manufacture activated carbon?

>> (4) Can activated carbon be regenerated and reused?

>> (5) How is the quality of activated carbon controlled during manufacturing?

● Citations:

Activated carbon is manufactured by transforming carbon-rich raw materials such as coal, coconut shell, wood, or biomass into an extremely porous, high–surface-area adsorbent through controlled carbonization and activation processes. Modern activated carbon production lines combine thermal, chemical, and mechanical steps to deliver consistent adsorption performance for water treatment, air and gas purification, food and beverage processing, chemical refining, and pharmaceutical applications. This article explains each stage of how activated carbon is manufactured and how different methods affect the final performance of activated carbon in industrial applications.[1][2][3]

What Is Activated Carbon

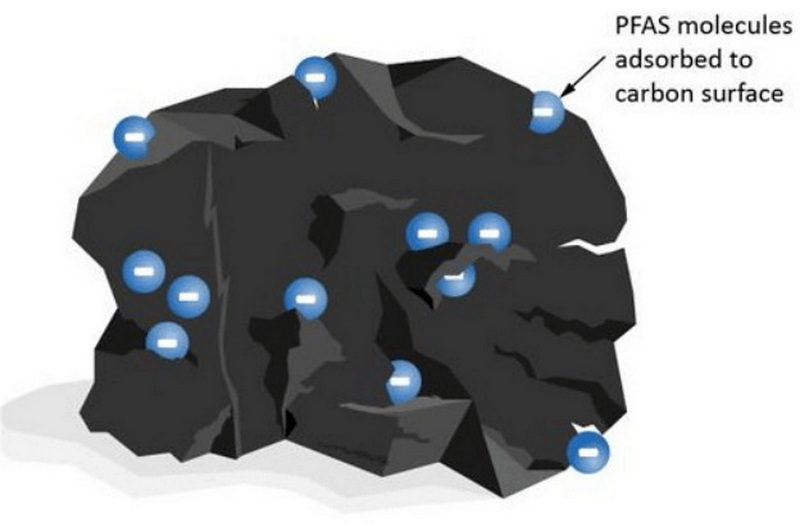

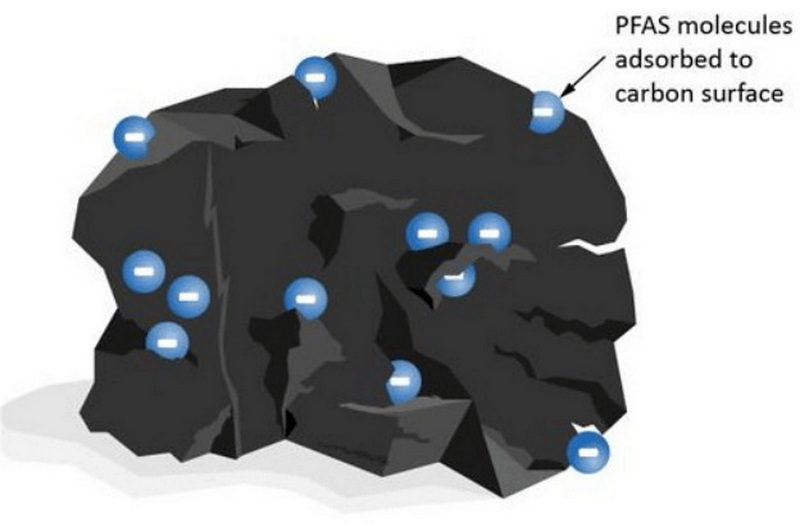

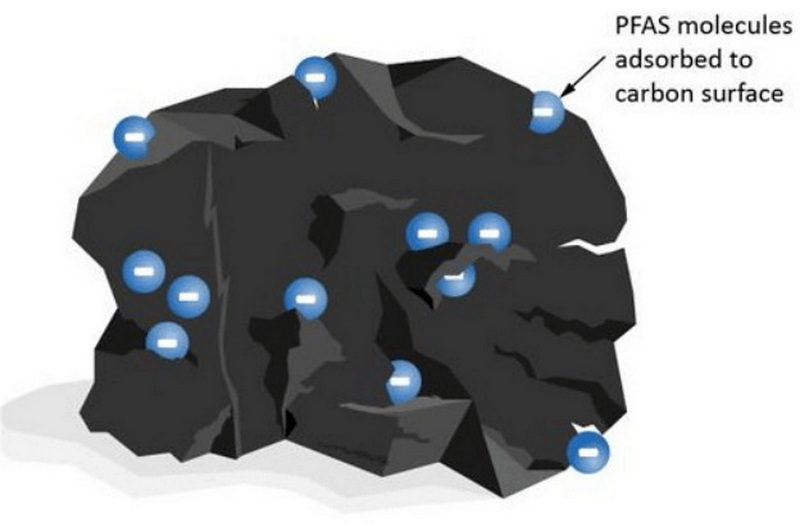

Activated carbon is a processed form of carbon with a highly porous structure and enormous internal surface area, typically ranging from 500 to over 2000 m² per gram. Because of this structure, activated carbon can adsorb a wide range of organic molecules, odors, colors, and certain inorganic species from liquids and gases.[2][4][3]

- Activated carbon is usually produced from coal, coconut shell, wood, peat, or other carbonaceous materials.[4][2]

- The main uses of activated carbon include drinking water purification, wastewater treatment, air and gas purification, solvent recovery, food and beverage decolorization, and pharmaceutical purification.[5][4]

Raw Materials For Activated Carbon

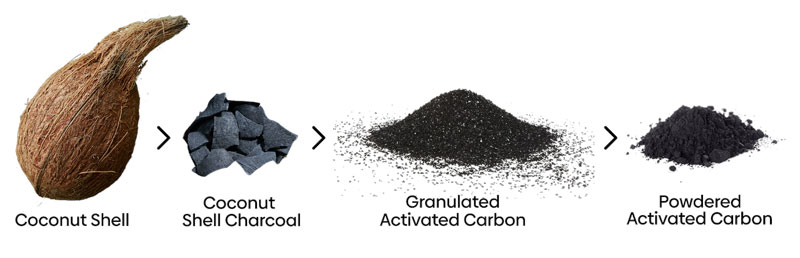

The manufacture of activated carbon starts with selecting a suitable carbon-rich raw material, which strongly influences pore structure, hardness, and cost. Each feedstock produces activated carbon with different performance characteristics for specific applications.[6][2][4]

- Coal-based activated carbon offers a balanced pore size distribution and high mechanical strength, making it suitable for municipal water, wastewater, and many industrial applications.[7][6]

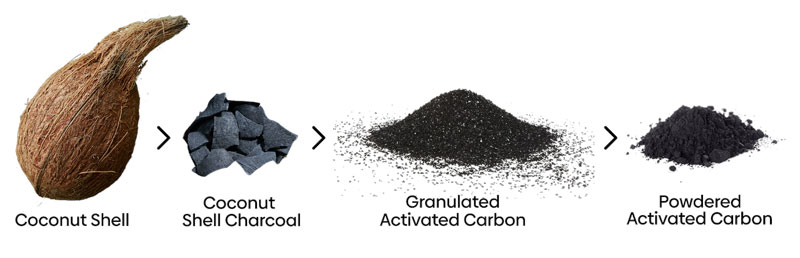

- Coconut shell activated carbon typically has a high proportion of micropores, excellent hardness, and is widely used for drinking water, VOC removal, and gold recovery.[8][9]

- Wood-based activated carbon tends to have more mesopores and macropores, making it effective for decolorization in food, sugar, and chemical industries.[10][2]

Overview Of The Activated Carbon Manufacturing Process

Although details vary by plant and raw material, the manufacturing process of activated carbon normally follows four major steps: carbonization, activation, washing and drying, and sizing and packaging. The goal is to convert dense carbonaceous raw materials into activated carbon with a tailored pore structure and surface chemistry while maintaining sufficient hardness and low ash content.[3][1][2]

- A typical process flow includes raw material pretreatment, controlled carbonization in an oxygen-limited environment, physical or chemical activation at elevated temperatures, and subsequent finishing operations.[1][10]

- Manufacturers often use rotary kilns, vertical furnaces, or retorts for carbonization and activation, combined with screening, grinding, and pelletizing systems to produce different forms of activated carbon.[7][1]

Step 1: Carbonization

Carbonization is the thermal decomposition of the raw material in the absence of oxygen to produce a carbon-rich char as the precursor of activated carbon. During carbonization, volatile components such as water, tars, and low-molecular-weight organics are driven off, leaving behind a basic pore skeleton.[11][10][3][1]

- Carbonization typically takes place at intermediate temperatures, commonly between 400 and 600 °C, in an inert or low-oxygen atmosphere such as nitrogen.[9][10]

- Rotary kilns, vertical furnaces, and retorts are often used, with controlled heating rates and residence times to avoid cracking, excessive fines formation, or incomplete devolatilization of the char.[1][7]

Step 2: Activation – Physical vs Chemical

Activation is the critical step where the char is converted into highly porous activated carbon by carefully controlled reactions that open and enlarge pores. There are two main activation routes used in manufacturing activated carbon: physical (steam or CO₂ activation) and chemical activation.[12][2][1]

- In physical activation, char is heated to high temperature (typically 800–1000 °C) and exposed to oxidizing gases such as steam or carbon dioxide, which selectively burn carbon and create a porous activated carbon structure.[13][9]

- In chemical activation, raw material or partially carbonized material is impregnated with chemical agents such as phosphoric acid or zinc chloride and then heated at lower temperatures (around 400–600 °C) to develop porosity directly.[10][2]

Physical Activation Of Activated Carbon

Physical activation is widely used for coal-based and coconut-shell activated carbon, especially where high hardness and thermal stability are required. The process involves separate carbonization and activation steps, enabling flexible control over burn-off and pore structure of activated carbon.[3][9][1]

- The carbonized char is heated in a furnace at high temperature, often between 800 and 1000 °C, under a controlled flow of steam or CO₂.[14][13]

- The oxidizing gas reacts with carbon to form CO and CO₂, gradually enlarging pores, increasing surface area, and turning the char into activated carbon with a selected degree of burn-off.[13][10]

Chemical Activation Of Activated Carbon

Chemical activation is commonly applied to wood-based or other biomass materials to produce low-density, highly porous activated carbon at comparatively lower temperatures. In this method, carbonization and activation occur simultaneously or in tightly integrated steps under the influence of chemical agents.[12][2][10]

- The raw material is impregnated or mixed with chemicals such as phosphoric acid, which act as dehydrating agents and promote pore formation during heating.[2][10]

- The impregnated material is then heated to around 400–600 °C in a furnace, where the chemical agent catalyzes the development of a porous activated carbon network without requiring very high temperatures.[10][2]

Step 3: Washing And Drying

After activation, the freshly manufactured activated carbon must be washed to remove residual chemicals, ash, and fines that could affect performance. Proper washing and drying are essential to ensure activated carbon meets purity standards for applications such as drinking water, food processing, and pharmaceuticals.[2][1][10]

- For chemically activated carbon, multiple washing stages with water and sometimes mild acid are used to remove phosphoric acid, zinc salts, or other reagents, followed by solid–liquid separation.[10][2]

- The washed activated carbon is then dried, typically in rotary dryers or fluidized-bed dryers, to achieve a stable moisture content and prevent clumping and microbial growth during storage.[1][10]

Step 4: Crushing, Sizing, And Forming

Once dried, activated carbon is processed into the required particle size and form to match different industrial applications. Manufacturers produce powdered, granular, and extruded activated carbon, each with specific advantages in liquid or gas phase systems.[5][6][1]

- Activated carbon may be crushed and sieved to obtain granular activated carbon (GAC), or finely ground to produce powdered activated carbon (PAC) for dosing into liquid streams.[6][5]

- For extruded activated carbon (also called pelletized carbon), fine powder is mixed with a binder and extruded into cylindrical pellets that provide low dust, good mechanical strength, and predictable pressure drop in gas-phase applications.[5][6]

Quality Control In Activated Carbon Manufacturing

Quality control is vital to ensure that each batch of activated carbon meets specified adsorption capacity, hardness, pore size distribution, and purity targets. Laboratory analysis is closely integrated with production to adjust activation conditions and maintain consistent performance for critical applications.[4][7][2]

- Common quality tests include iodine number, methylene blue value, BET surface area, ash content, hardness, pH, and particle size distribution, all of which characterize activated carbon performance.[6][2]

- For drinking water, food, and pharmaceutical uses, additional tests for heavy metals, leachable impurities, and compliance with relevant standards are applied to ensure safe activated carbon products.[4][2]

Types Of Activated Carbon By Form And Application

Different physical forms of activated carbon are optimized for specific operating conditions in liquid or gas systems. Selecting the right type of activated carbon is as important as the manufacturing method for achieving target purification performance.[5][4][6]

- Powdered activated carbon (PAC) is a fine powder dosed into water or process liquids for taste and odor control, color removal, and removal of trace organics.[4][6]

- Granular activated carbon (GAC) consists of larger particles used in fixed or fluidized beds for municipal water treatment, industrial wastewater, and some gas purification systems.[6][5]

- Extruded activated carbon (EAC) in pellet form provides high mechanical strength and low dust for air and gas purification, solvent recovery, and soil vapor extraction.[5][6]

Environmental And Regeneration Aspects

Manufacturing and using activated carbon are closely linked with environmental protection, both in terms of pollution control and resource efficiency. Spent activated carbon can often be thermally reactivated, which reduces waste and lowers lifecycle cost compared with one-time-use adsorbents.[14][3][2][10]

- Modern activated carbon plants incorporate off-gas treatment, energy recovery, and, in the case of chemical activation, recovery of acids such as phosphoric acid to reduce environmental impact.[7][10]

- Thermal reactivation of spent activated carbon involves controlled high-temperature treatment to burn off adsorbed organics and restore much of the original adsorption capacity, making the process more sustainable.[3][2]

Conclusion

Activated carbon is manufactured through a carefully controlled sequence of steps that convert selected raw materials into high-performance adsorbents for liquid and gas purification. By optimizing carbonization, physical or chemical activation, washing, drying, and particle shaping, producers can tailor activated carbon to meet the demanding requirements of water treatment, air and gas purification, food and beverage processing, chemical refining, and pharmaceutical applications worldwide.[3][1][2]

FAQs About How Activated Carbon Is Manufactured

(1) How is activated carbon different from regular charcoal?

Activated carbon is produced by carbonization followed by activation, which creates a highly developed pore structure and much larger internal surface area than regular charcoal. This makes activated carbon far more effective for adsorption in water and gas purification compared with untreated charcoal.[2][3][1][4]

(2) Which activation method is better: physical or chemical?

Physical activation is often preferred for coal-based and coconut-shell activated carbon when high hardness and thermal stability are needed, while chemical activation is suitable for wood-based or biomass feedstocks requiring high porosity at lower temperatures. The “better” method depends on the target pore structure, application, cost, and environmental requirements for the activated carbon product.[9][12][10][2]

(3) Why are different raw materials used to manufacture activated carbon?

Different raw materials produce activated carbon with distinct pore size distributions, hardness, and ash content, which influence performance in specific applications. For example, coconut shell activated carbon is usually rich in micropores for VOC removal, coal-based activated carbon offers balanced porosity, and wood-based activated carbon provides more mesopores for decolorization.[2][4][6]

(4) Can activated carbon be regenerated and reused?

Yes, many types of spent activated carbon from industrial and municipal applications can be thermally reactivated in specialized furnaces to restore a large portion of their adsorption capacity. Regeneration reduces waste volumes and often lowers overall treatment cost compared with continuous purchase of fresh activated carbon.[14][3][2]

(5) How is the quality of activated carbon controlled during manufacturing?

Manufacturers routinely test parameters such as iodine number, surface area, pore size distribution, hardness, ash content, and particle size to ensure activated carbon meets specification. For sensitive uses like drinking water, food, and pharmaceuticals, additional purity and safety tests are applied before releasing activated carbon to the market.[4][6][2]

Citations:

[1](https://www.dec.group/_docs_/ACA-docs/activated-carbon-production-ACA_en.html)

[2](https://www.activatedcarbon.org/activated-carbon/production/)

[3](https://feeco.com/introduction-to-activated-carbon/)

[4](https://www.rbhltd.com/product/activated-carbon/)

[5](https://www.carbotech.de/en/product-forms-of-activated-carbons/)

[6](https://qizhongcarbon.com/blog/types-of-activated-carbon/)

[7](https://rotarykilnfactory.com/how-to-make-coal-based-activated-carbon/)

[8](https://www.suneetacarbons.com/process.html)

[9](https://www.sciencedirect.com/science/article/abs/pii/S138718111100566X)

[10](https://heycarbons.com/manufacture-of-activated-carbon/)

[11](https://www.sciencedirect.com/topics/engineering/preparing-activated-carbon)

[12](https://pubs.rsc.org/en/content/articlelanding/2021/ta/d1ta00765c)

[13](https://pmc.ncbi.nlm.nih.gov/articles/PMC8466215/)

[14](https://www.sciencedirect.com/science/article/abs/pii/S0169433222030884)

[15](https://www.youtube.com/watch?v=GNKeps6pIao)