Content Menu

● Is Powdered Activated Carbon Explosive?

● What Is Powdered Activated Carbon?

● Combustible Dust and Dust Explosion Basics

● Is Powdered Activated Carbon a Combustible Dust?

● When Can Powdered Activated Carbon Explode?

● Fire Hazards of Powdered Activated Carbon

● Industrial Standards and Regulations

● Safe Handling and Storage of Powdered Activated Carbon

● Explosion Prevention and Protection Measures

● Electrostatic and Ignition Source Control

● Housekeeping and Facility Management

● Special Hazards: Wet Activated Carbon and Confined Spaces

● Applications of Powdered Activated Carbon and Practical Safety Tips

● Summary Table: Risk and Controls for Powdered Activated Carbon

● Conclusion

● FAQ About Powdered Activated Carbon Explosion Risk

>> 1. Is powdered activated carbon classified as explosive?

>> 2. Under what conditions can powdered activated carbon explode?

>> 3. How can facilities reduce the explosion risk of powdered activated carbon?

>> 4. Is wet powdered activated carbon still hazardous?

>> 5. Which standards apply to powdered activated carbon as a combustible dust?

● Citations:

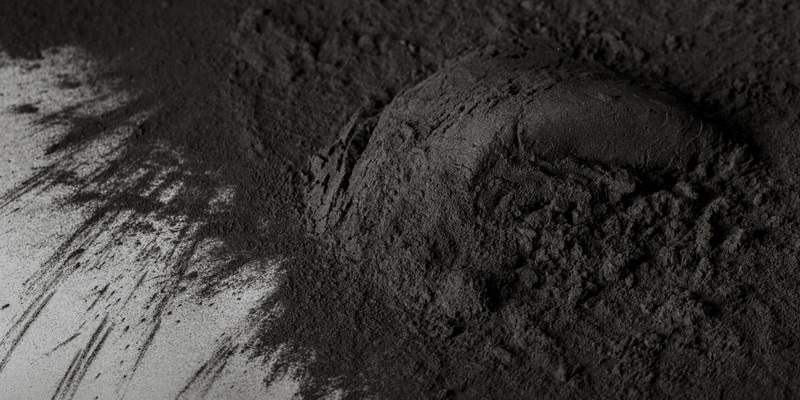

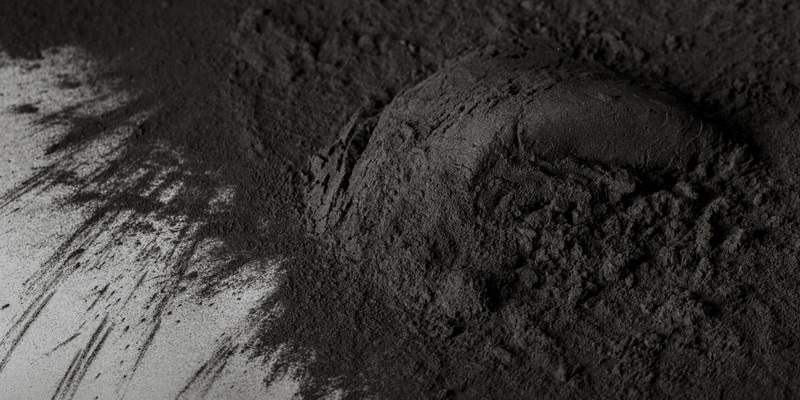

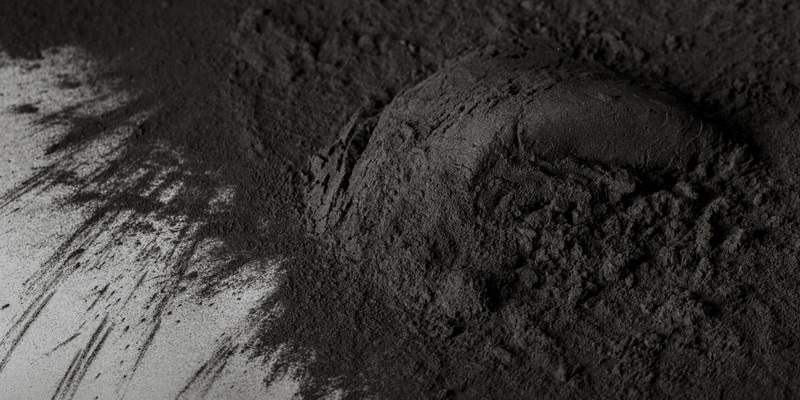

Is powdered activated carbon explosive? Powdered activated carbon is not a high explosive, but it is a combustible dust that can cause fire and dust explosions when fine particles are dispersed in air and exposed to an ignition source in a confined or semi‑confined space.[1][2]

Is Powdered Activated Carbon Explosive?

Powdered activated carbon is classified as a weakly explosive combustible dust (dust explosion class St1) when suspended in air at sufficient concentration and exposed to a strong ignition source. In normal solid or slightly dusty conditions it behaves as a flammable solid rather than an explosive, but poor housekeeping and uncontrolled dust clouds can turn it into a serious explosion hazard in industrial environments.[2][3][1]

What Is Powdered Activated Carbon?

Powdered activated carbon is a finely ground form of activated carbon with a very high internal surface area, typically produced from coal, wood, or coconut shells and used for adsorption in water treatment, air and gas purification, food and beverage, chemical, and pharmaceutical processes. Because powdered activated carbon consists of very small particles, it can easily become airborne and form dust clouds, which is the main reason it must be evaluated for combustible dust and dust explosion risk.[4][5][6][2]

Powdered activated carbon is usually delivered and stored in bags, big bags, or silos and then dosed into process streams as a slurry or dry powder. In many facilities it is preferred over granular activated carbon for rapid adsorption and easier dosing, but this also increases the proportion of respirable particles and the potential for dust accumulation on floors, beams, and equipment.[5][7][4]

Combustible Dust and Dust Explosion Basics

Combustible dust is any finely divided combustible solid that can burn rapidly when dispersed in air, and many materials that are non‑hazardous in bulk form become dangerous once ground into fine powder. Safety standards such as NFPA 652 and NFPA 654 define combustible dust hazards and require dust hazard analysis (DHA) for materials like activated carbon that can form explosible dust‑air mixtures.[8][9][10][11]

A dust explosion requires five elements often called the “dust explosion pentagon”: fuel (combustible dust), oxidant (air), dispersion (dust cloud), confinement, and an ignition source with sufficient energy. When these conditions are present, a primary explosion in a piece of equipment or duct can stir up more settled dust and cause secondary explosions that are frequently far more destructive than the initial event.[12][11][8]

Is Powdered Activated Carbon a Combustible Dust?

Safety data sheets for activated carbon consistently state that powdered activated carbon may form combustible dust concentrations in air and can create a dust explosion hazard when finely dispersed in the presence of an ignition source. Many SDS documents report a minimum explosible concentration for activated carbon dust around 50–140 g/m³ of air, confirming that airborne powdered activated carbon can support deflagration.[13][3][1][5]

Typical test data for activated carbons show Kst values (dust deflagration index) in the range of about 43–113 bar·m/s, which places powdered activated carbon in dust explosion class St1, defined as “weakly explosive.” Even though “weakly explosive” sounds mild, this class can still generate maximum explosion pressures in the 6–8.6 bar range inside enclosed equipment, which is more than enough to rupture vessels, ducts, and filters if protection is inadequate.[11][1][2]

When Can Powdered Activated Carbon Explode?

Powdered activated carbon becomes explosible primarily when it is dry, finely divided, and suspended as a cloud inside equipment such as silos, pneumatic conveying lines, dust collectors, hoppers, or mixers. If a spark, hot surface, electrostatic discharge, or other ignition source is present while the dust concentration is above the minimum explosible concentration, a rapid flame front and pressure rise—deflagration—can occur.[3][14][13][5]

Secondary explosions are a particular concern where housekeeping is poor and layers of powdered activated carbon dust accumulate on horizontal surfaces such as beams, rafters, cable trays, and machine tops. A small primary event inside equipment can blow hot gases and burning particles into the building, lofting the settled powdered activated carbon into a dust cloud that then ignites and causes large‑scale damage.[12][8][11]

Fire Hazards of Powdered Activated Carbon

Beyond explosion risk, powdered activated carbon is combustible and can sustain smoldering fires, especially when oxygen and heat are available. Safety documents warn that activated carbon has high surface area which can promote self‑heating during oxidation, and smoldering hotspots may persist for long periods after a fire appears to be extinguished.[15][4][5]

If activated carbon is saturated with certain organic compounds, it can ignite more readily, and some activated carbon systems used for vapor control have experienced fires when operating or regenerating with flammable adsorbates. Fire‑fighting guidance typically recommends water spray, dry chemical, foam, or carbon dioxide for activated carbon fires and warns against high‑pressure streams that could disperse dust and create explosive dust‑air mixtures.[16][6][13][5]

Industrial Standards and Regulations

Modern combustible dust management for materials like powdered activated carbon is guided by NFPA standards, particularly NFPA 652 (general combustible dust), NFPA 654 (combustible particulate solids), and newer consolidated guidance such as NFPA 660. These standards require owners and operators to identify combustible dust hazards, characterize materials (Kst, Pmax, MEC, MIE, MIT), conduct dust hazard analyses, and implement engineering and administrative controls.[17][9][10]

OSHA treats combustible dust, including activated carbon, as a recognized hazard under the General Duty Clause and references NFPA standards in enforcement and guidance documents. Regulatory and consensus standards emphasize that seemingly inert materials like powdered activated carbon can still be hazardous if they generate combustible dust clouds in process equipment or buildings.[9][16][11]

Safe Handling and Storage of Powdered Activated Carbon

SDS guidance consistently advises avoiding the creation of dust when handling powdered activated carbon and using local exhaust ventilation to keep airborne concentrations as low as reasonably practicable. Good practice includes sealed transfer equipment, covered conveyors, carefully designed bag dumping stations with dust capture, and enclosed dosing systems that minimize release of powdered activated carbon to the workplace.[7][1][4][5]

Storage recommendations typically specify dry, cool, well‑ventilated areas away from strong oxidizers, strong acids, ignition sources, and incompatible materials. Containers and silos of powdered activated carbon should be protected from physical damage, and adequate spacing is recommended to limit fire spread and allow heat dissipation in case of smoldering or burning material.[6][1][2]

Explosion Prevention and Protection Measures

To control the explosion risk of powdered activated carbon, facilities usually combine prevention (avoiding an ignitable atmosphere or ignition source) and protection (limiting consequences if an explosion occurs). Prevention measures include inerting with nitrogen where feasible, minimizing dust clouds by using wet systems or enclosed transfer, and specifying non‑sparking, grounded, and bonded equipment to control static discharge around powdered activated carbon systems.[10][1][5][11]

Explosion protection strategies may involve explosion venting of vessels and dust collectors, explosion suppression systems, and explosion isolation devices such as fast‑acting valves or chemical barriers that prevent flame propagation between connected equipment. A dust hazard analysis is used to determine where such measures are required for handling, conveying, storing, and dosing powdered activated carbon.[17][9][10][11]

Electrostatic and Ignition Source Control

Because powdered activated carbon is a fine, non‑conductive particulate, static electricity can accumulate on dust particles and on plastic or ungrounded equipment surfaces during conveying, mixing, and bag emptying. Guidance therefore stresses grounding and bonding of all metal parts of transfer, blending, and dust collection equipment, along with control of charging in pneumatic transport systems.[1][4][5]

Other potential ignition sources around powdered activated carbon include open flames, hot surfaces, frictional heating, mechanical sparks, and electrical equipment that does not meet appropriate hazardous location classifications. Facilities handling powdered activated carbon should select motors, lights, and control devices rated for the relevant dust environment and maintain them to prevent overheating and arcing.[14][11]

Housekeeping and Facility Management

Housekeeping is a frontline defense against both fire and explosion hazards from powdered activated carbon, because thick dust layers greatly increase the fuel available for secondary explosions. NFPA guidance highlights the need for regular cleaning of structural members, overheads, equipment surfaces, and hidden spaces where powdered activated carbon dust can settle unnoticed.[8][9][11][12]

Cleaning methods should avoid creating clouds of powdered activated carbon; many safety documents recommend vacuuming with explosion‑proof equipment instead of dry sweeping or compressed air blow‑down. Documented maintenance programs, inspection of dust collectors and filters, and prompt repair of leaks and spills help keep combustible powdered activated carbon under control.[5][11][12]

Special Hazards: Wet Activated Carbon and Confined Spaces

While dry powdered activated carbon is associated with combustible dust and explosion hazards, wet activated carbon poses a different risk by removing oxygen from air in confined spaces. Several safety data sheets warn that workers entering carbon vessels, filters, or tanks containing wet activated carbon must test for oxygen deficiency and follow confined space entry procedures.[6][1]

Spent powdered activated carbon can also exhibit hazards associated with adsorbed substances, including toxicity, corrosivity, or additional flammability, so handling and disposal must consider both the carbon and the captured contaminants. Proper assessment, personal protective equipment, and, if necessary, classification as hazardous waste are important when managing spent powdered activated carbon from industrial processes.[4][5][6]

Applications of Powdered Activated Carbon and Practical Safety Tips

In water treatment, powdered activated carbon is widely used for taste and odor control, removal of organic micropollutants, and treatment of industrial wastewater, often dosed as a slurry to reduce dust generation. Water plants can reduce combustible dust risk by designing enclosed unloading and slurry‑making systems, providing dust collection at powder addition points, and maintaining good housekeeping around chemical storage areas.[4][5][6]

In air and gas purification, food and beverage, chemical, and pharmaceutical processes, powdered activated carbon may be added to process streams, used in batch treatment, or applied in decolorization and purification steps. For these applications, safe design of powder feeding, storage silos, bag filters, and dust extraction systems is essential to keep powdered activated carbon dust below explosible levels and prevent ignition.[10][5][6][4]

Summary Table: Risk and Controls for Powdered Activated Carbon

| Aspect | Key points for powdered activated carbon |

| Material classification | Combustible dust, dust explosion class St1 (weakly explosive) when dispersed in air. generalcarbon+1 |

| Typical test data | Kst roughly 43–113 bar·m/s, Pmax about 6–8.6 bar in explosion tests. generalcarbon+1 |

| Main explosion scenario | Dry, fine powder cloud in equipment or building plus ignition source and some confinement. uwaterloo+1 |

| Fire behavior | Can smolder and self‑heat due to high surface area; hotspots may persist after fire. norit+1 |

| Standards and guidance | NFPA 652, NFPA 654, newer NFPA 660, and OSHA combustible dust guidance. camfilapc+2 |

| Prevention measures | Minimize dust clouds, control ignition sources, ground and bond equipment, good housekeeping. generalcarbon+1 |

| Protection measures | Explosion venting, suppression, and isolation on equipment handling powdered activated carbon. nfpa+1 |

| Special notes | Wet activated carbon can deplete oxygen in confined spaces; spent carbon may inherit hazards. generalcarbon+1 |

Conclusion

Powdered activated carbon is not a detonating explosive, but it is a combustible dust that can create weak to moderate dust explosions when dispersed as a cloud in air and ignited in confined or semi‑confined spaces. Industrial users in water treatment, air and gas purification, food and beverage, chemical, and pharmaceutical sectors must recognize powdered activated carbon as a potential combustible dust, perform dust hazard analyses, and implement appropriate prevention and protection measures including enclosure, ventilation, ignition control, explosion protection, and disciplined housekeeping.[2][1][5][10][17]

FAQ About Powdered Activated Carbon Explosion Risk

1. Is powdered activated carbon classified as explosive?

Powdered activated carbon is generally classified as a weakly explosive combustible dust (dust explosion class St1) rather than a high explosive. It can cause deflagration and pressure damage in enclosed equipment when a dust cloud forms and encounters a sufficient ignition source, so it must be treated as an explosion hazard in industrial handling systems.[13][3][1][2]

2. Under what conditions can powdered activated carbon explode?

An explosion involving powdered activated carbon typically requires a dry, finely dispersed dust cloud, enough oxygen, some degree of confinement, and an ignition source such as a spark, hot surface, or electrostatic discharge. These conditions most often occur inside silos, bag filters, pneumatic conveyors, hoppers, and mixers, or in rooms where heavy dust deposits can be lofted into the air.[3][14][5][11]

3. How can facilities reduce the explosion risk of powdered activated carbon?

Facilities can reduce risk by minimizing dust generation, enclosing transfer equipment, providing effective local exhaust and dust collection, and implementing rigorous housekeeping to prevent dust layers. Grounding and bonding, using appropriately rated electrical equipment, and designing explosion venting or suppression and isolation systems where needed all contribute to safer handling of powdered activated carbon.[1][5][10][11]

4. Is wet powdered activated carbon still hazardous?

Wet or slurry forms of powdered activated carbon greatly reduce combustible dust explosion risk, but they introduce other hazards such as oxygen depletion in confined spaces and potential release of adsorbed contaminants. Workers entering vessels or tanks containing wet activated carbon must test the atmosphere and follow confined space entry procedures, and spent wet carbons should be evaluated for chemical hazards associated with the substances they have adsorbed.[6][1][4]

5. Which standards apply to powdered activated carbon as a combustible dust?

Key references for managing combustible dust hazards from powdered activated carbon include NFPA 652 (fundamentals), NFPA 654 (combustible particulate solids), and the consolidated NFPA 660, as well as OSHA's combustible dust guidance and technical manuals. These documents require material testing where needed, dust hazard analysis, and implementation of engineering, administrative, and protective measures suited to the level of risk in each facility handling powdered activated carbon.[9][10][11][17]

Citations:

[1](https://generalcarbon.com/activated-carbon/activated-carbon-msds/)

[2](https://ceramaterials.com/wp-content/uploads/2019/10/ActivatedCarbon-SDS.pdf)

[3](https://nrf.aux.eng.ufl.edu/_files/msds/2/Activated%20Carbon%20.pdf)

[4](https://norit.com/hubfs/S-PAC-USA&Canada-EN-1.pdf?hsLang=en)

[5](https://www.sorbtech.com/msds/SDS%20Activated%20Carbon(9-12-22).pdf)

[6](https://www.calgoncarbon.com/app/uploads/138_CENTAUR_HSL_8X30.pdf)

[7](https://www.chemsupply.com.au/documents/CL0263CH1F.pdf)

[8](https://www.controlledairdesign.com/images/uploads/files/NFPA_652_Second_Draftv1_Jan14.pdf)

[9](https://www.awpa.org/wp-content/uploads/2020/06/NFPA-652-2019.pdf)

[10](https://www.nfpa.org/codes-and-standards/nfpa-654-standard-development/654)

[11](https://www.osha.gov/sites/default/files/otm_secIV_chap6.pdf)

[12](https://www.csb.gov/file.aspx?DocumentId=5588)

[13](https://uwaterloo.ca/giga-to-nanoelectronics-centre/sites/default/files/uploads/files/charcoal_activated.pdf)

[14](https://www.sigmaaldrich.com/US/en/sds/sial/05105)

[15](https://redox.com/wp-content/sds/870.pdf)

[16](http://www.osha.gov/publications/hib19970730)

[17](https://camfilapc.com/blog/understanding-nfpa-660-the-new-standard-for-combustible-dust-safety/)

[18](https://www.fishersci.com/store/msds?partNumber=AAH366910P&productDescription=CRBN+PWR+ACTVTD+NORIT+D10+2KG&vendorId=VN00024248&countryCode=US&language=en)

[19](https://www.laddresearch.com/lanotattachments/download/file/id/541/store/1/60808sds.pdf)

[20](https://www.spectrumchemical.com/MSDS/C1214_AGHS.pdf)