Content Menu

● What Determines How Long Activated Carbon Lasts?

● Typical Lifespan in Water Treatment Systems

● How Long Activated Carbon Lasts in Air and Gas Purification

● How Long Activated Carbon Lasts in Aquariums

● Signs That Activated Carbon Has Reached the End of Its Life

● Why Manufacturers Suggest Time or Gallon Limits

● How Operating Conditions Affect How Long Activated Carbon Lasts

● Can Activated Carbon Be Regenerated to Extend Its Life?

● How Long Activated Carbon Lasts by Application (Overview Table)

● Recommended Replacement Intervals for Different Users

● How to Make Activated Carbon Last Longer

● Conclusion

● FAQs About How Long Activated Carbon Lasts

>> 1) How long does activated carbon last in drinking water filters?

>> 2) How long does activated carbon last in industrial gas‑phase filters?

>> 3) How often should activated carbon be replaced in aquariums?

>> 4) Does unused activated carbon expire in storage?

>> 5) Can activated carbon be regenerated to extend its life?

● Citations:

Activated carbon does not have a fixed universal lifetime; how long activated carbon lasts depends on the medium (water or air), contaminant load, flow rate, carbon quality, and system design. In practice, activated carbon may last from a few weeks in small aquarium filters to 1–3 years in large industrial gas‑phase beds or even longer when regenerated professionally.

What Determines How Long Activated Carbon Lasts?

Activated carbon lifespan is controlled by how quickly its pores become saturated with adsorbed contaminants. The more contaminants the activated carbon must handle, the faster its adsorption capacity is consumed and the sooner the activated carbon needs to be replaced or regenerated.

Key factors that determine how long activated carbon lasts include:

- Type of application: water treatment, air and gas purification, aquariums, food and beverage, chemical, or pharmaceutical processes.

- Flow rate and contact time between the fluid and the activated carbon.

- Incoming contaminant concentration and type (chlorine, VOCs, organics, sulfur compounds, odors, heavy organics, etc.).

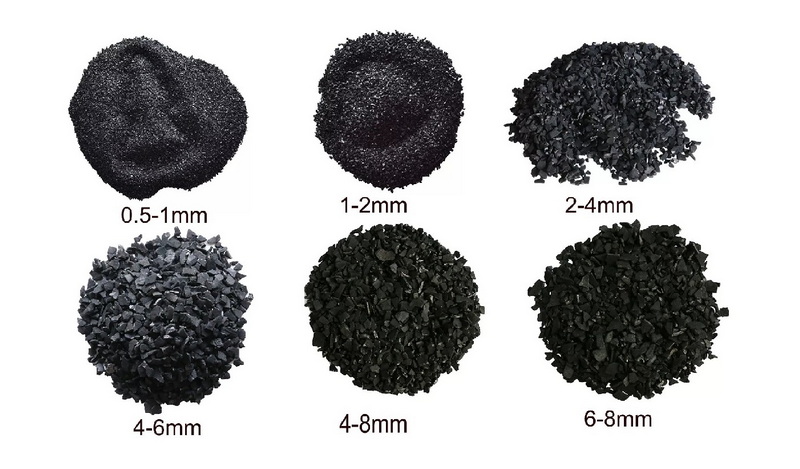

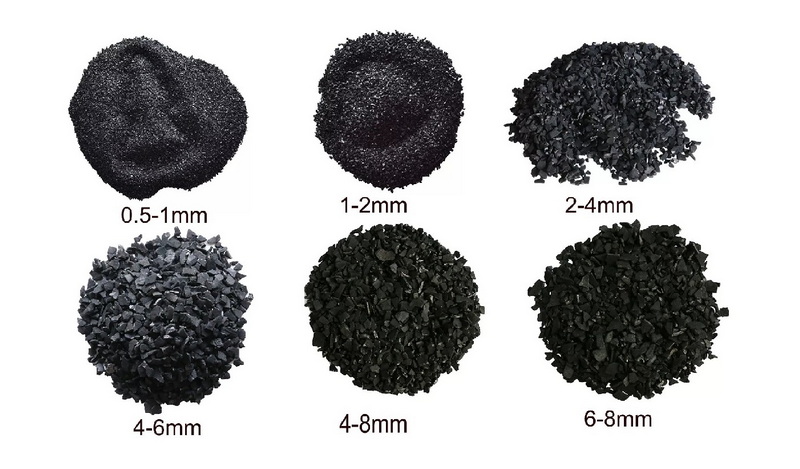

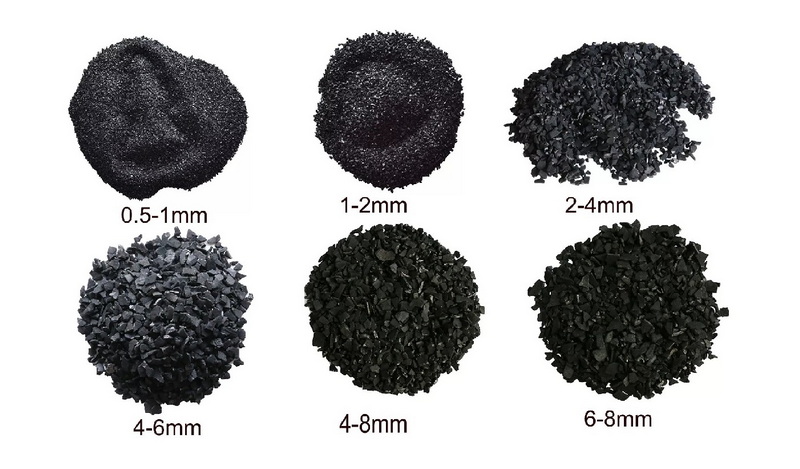

- Type of activated carbon (granular activated carbon, powdered activated carbon, carbon block, coconut shell activated carbon, coal‑based activated carbon, etc.).

- Bed depth, vessel design, and whether pre‑filtration is used.

Typical Lifespan in Water Treatment Systems

In water treatment, “how long activated carbon lasts” is often expressed in months of service or volume of water treated. Many residential and light commercial activated carbon filters are rated for 6–12 months of use, or for a specific number of gallons such as 100,000 gallons for a whole‑house granular activated carbon cartridge.

Typical ranges for how long activated carbon lasts in water systems:

- Under‑sink and point‑of‑use activated carbon filters: about 6–12 months under normal household use.

- Whole‑house granular activated carbon filters: around 6–12 months or 50,000–100,000 gallons, depending on water quality and family size.

- Shower filters with activated carbon media: often recommended replacement every 6–12 months, and never longer than one year.

Even if water still looks clear, overstaying the recommended life can lead to pore saturation, reduced adsorption capacity, and possible release of previously captured contaminants back into the water.

How Long Activated Carbon Lasts in Air and Gas Purification

In air and gas purification, activated carbon is installed in beds or cartridges that adsorb volatile organic compounds, odors, and other gas‑phase contaminants. In these systems, how long activated carbon lasts is typically described as a range from several months up to a few years, depending on loading and design.

Typical gas‑phase lifespan indications:

- Small odor control filters in HVAC or room purifiers: often 3–12 months of effective performance.

- Industrial activated carbon bed filters for raw CO₂ gas treatment: carbon life of about 1–3 years before regeneration or replacement when treating organic and sulfur compounds.

- Large industrial adsorbers: bed life is engineered using gas‑phase isotherm data and impurity loading data to hit a desired service time before changeout, often measured in months or years.

Because gas‑phase adsorption generates heat and depends on concentration, temperature, humidity, and competing contaminants, engineers calculate how long activated carbon lasts using isotherm data and impurity flux (concentration × flow).

How Long Activated Carbon Lasts in Aquariums

Aquarium users often ask how long activated carbon lasts in small filters for fish tanks. In aquariums, activated carbon rapidly adsorbs dissolved organics, color, odors, and residual medications, so capacity can be used up quickly.

Common guidelines for aquarium activated carbon:

- A significant portion of adsorption happens in the first week, and most remaining capacity is consumed over the next two weeks.

- Many aquarium experts recommend changing activated carbon about once per month, or every 3–4 weeks, especially in tanks with high bioload or heavy feeding.

- Some aquarium hobbyists use activated carbon temporarily (for example, after medication) and then remove it once the targeted contaminants are cleared.

If activated carbon is left too long in an aquarium filter, performance declines and the media can become clogged with debris, reducing flow and filtration efficiency.

Signs That Activated Carbon Has Reached the End of Its Life

Because activated carbon gradually loses capacity, it is important to monitor both water or air quality and system behavior to know when the activated carbon is “spent.” It is difficult to see inside the pores, so operators look for indirect warning signs.

Common signs that activated carbon is no longer effective:

- Return of chlorine taste, odor, or discoloration in drinking water downstream of an activated carbon filter.

- Noticeable odors or VOC smells bypassing an activated carbon air or gas filter that previously removed them.

- Decreased water flow or pressure drop across an activated carbon cartridge, indicating blockage with particles and organic matter.

- Laboratory testing shows contaminants no longer being reduced to target levels.

For aquariums, a simple way to tell whether activated carbon is exhausted is to test water parameters and observe odor, color, and clarity over time.

Why Manufacturers Suggest Time or Gallon Limits

Many users ask why activated carbon filters must be changed every 6–12 months even if water seems fine. Manufacturers base their recommendations on a combination of media capacity, typical usage, and safety margins.

Reasons behind these limits include:

- Activated carbon pores gradually fill up until no more adsorption is possible.

- Overused activated carbon can become a breeding site for bacteria if left wet and stagnant.

- If activated carbon stays in service too long, previously adsorbed contaminants may desorb and leach back into the water.

- Filter housings, gaskets, and other components are also designed for a certain service life.

Even when water taste remains acceptable, following the recommended replacement interval ensures that activated carbon continues to perform reliably and safely.

How Operating Conditions Affect How Long Activated Carbon Lasts

The same amount of activated carbon can last very different lengths of time depending on how it is used. Engineers and operators can extend how long activated carbon lasts by optimizing operating conditions.

Key operating factors:

- Flow rate and empty bed contact time (EBCT): lower flow and longer contact time often improve adsorption efficiency and can extend bed life.

- Contaminant concentration: higher concentrations consume capacity faster; dilute streams allow activated carbon to last longer.

- Pre‑filtration: sediment or mechanical pre‑filters remove particles so they do not plug the activated carbon bed, prolonging service life.

- Temperature and humidity in gas‑phase systems: higher temperature can reduce adsorption capacity, while humidity affects some contaminants differently.

- Bed depth and vessel design: deeper beds and well‑designed distributors promote uniform flow and full utilization of the activated carbon bed.

For large industrial systems, design often targets a desired bed life (for example, 12–24 months) and then uses isotherm data to size the activated carbon volume accordingly.

Can Activated Carbon Be Regenerated to Extend Its Life?

Instead of disposing of spent activated carbon, many industrial users regenerate or reactivate the media to restore adsorption capacity. In this context, “how long activated carbon lasts” includes multiple cycles of use and reactivation.

Common approaches to regeneration and reactivation:

- Off‑site high‑temperature thermal reactivation in specialized furnaces, where organic contaminants are driven off and new surface area is created in the granular activated carbon.

- On‑site steam or hot gas regeneration for certain gas‑phase applications, especially when contaminants are desorbed and the activated carbon is reused.

- Chemical regeneration for some specialized adsorbates, though this is less common for general water and air treatment.

Thermally reactivated granular activated carbon is widely used in water and wastewater treatment, enabling multiple reuse cycles and significantly extending practical life while reducing overall cost and environmental impact.

How Long Activated Carbon Lasts by Application (Overview Table)

| Application / System | Typical form of activated carbon | Typical lifespan range |

| Under‑sink drinking water filters | Granular activated carbon / carbon block | About 6–12 months |

| Whole‑house water filters | Granular activated carbon | About 6–12 months or ~100,000 gallons |

| Shower filters | Activated carbon cartridge | About 6–12 months (never more than 1 year) |

| Small air purifiers / odor filters | Granular activated carbon pads or cartridges | About 3–12 months |

| Industrial CO₂ gas treatment beds | Granular activated carbon bed | About 1–3 years before changeout or reactivation |

| General industrial air / gas treatment | Granular activated carbon bed | Months to several years, designed via isotherms |

| Aquariums (home tanks) | Granular activated carbon filter media | About 3–4 weeks to 1 month |

| Aquarium chemical filter media replacement | Granular activated carbon / mixed pads | Roughly once per month |

| Residential carbon filter cartridges (generic) | Granular activated carbon / carbon block | Manufacturer rating, often 6–12 months |

Recommended Replacement Intervals for Different Users

For practical decision‑making, it is useful to translate “how long activated carbon lasts” into simple replacement rules. These rules help assure performance even when detailed testing is not available.

Typical recommendations:

- Replace point‑of‑use activated carbon water filters every 6–12 months or according to gallon ratings.

- Replace whole‑house activated carbon cartridges at least every 12 months, and sooner in areas with high chlorine, organics, or odor problems.

- Replace small activated carbon air filters every 3–12 months, depending on odor level and usage time per day.

- In aquariums, replace activated carbon media about once per month, especially in heavily stocked tanks.

Industrial users should follow supplier design documents and monitor breakthrough curves, pressure drop, and effluent quality to schedule changeouts or regeneration of large activated carbon beds.

How to Make Activated Carbon Last Longer

There are several practical strategies to extend how long activated carbon lasts without compromising water or air quality. Proper system design and maintenance can significantly increase the useful life of activated carbon media.

Measures to extend service life:

- Use sediment or pre‑filters to remove suspended solids before the activated carbon stage.

- Size the activated carbon bed for adequate contact time and reasonable superficial velocity.

- Choose high‑quality activated carbon (for example, coconut shell activated carbon with high hardness and optimized pore structure) for demanding applications.

- Avoid sudden overloads of chemicals that can saturate the activated carbon bed prematurely.

- For industrial systems, plan periodic regeneration or reactivation of granular activated carbon rather than full disposal.

Well‑engineered systems with robust activated carbon beds and proper operation can achieve predictable, long‑term performance and lower lifecycle costs.

Conclusion

How long activated carbon lasts is not a single fixed number; it ranges from weeks in small aquarium filters to 6–12 months in residential water filters and up to 1–3 years or more in large industrial beds, especially when regeneration is used. Proper design, correct selection of activated carbon type, and regular maintenance based on contaminant load and performance monitoring are essential to achieve reliable adsorption, safe operation, and optimized lifecycle costs in water treatment, air and gas purification, food and beverage, chemical, and pharmaceutical applications.

Contact us to get more information!

FAQs About How Long Activated Carbon Lasts

1) How long does activated carbon last in drinking water filters?

Activated carbon in typical household drinking water filters lasts about 6–12 months under normal usage, or until the rated gallon capacity is reached, whichever comes first.

If water usage is high or incoming water has high chlorine, organics, or odor problems, the activated carbon may reach capacity sooner and should be replaced more frequently to keep adsorption performance and hygiene under control.

2) How long does activated carbon last in industrial gas‑phase filters?

In industrial gas‑phase filters, activated carbon can last from several months up to 1–3 years before changeout or regeneration, depending on contaminant loading, gas composition, temperature, and bed design.

Engineers use isotherm data and impurity flux calculations to design activated carbon bed volume for a target bed life, and they monitor outlet concentrations and pressure drop to determine the optimal replacement or regeneration schedule.

3) How often should activated carbon be replaced in aquariums?

In most aquariums, activated carbon should be replaced about once per month, because much of the adsorption capacity is used in the first few weeks and the media gradually becomes saturated and clogged with organic matter.

Aquarists often test water parameters and observe color and odor; if water starts to smell, turn yellow, or medications need to be removed, fresh activated carbon is installed and old media is discarded.

4) Does unused activated carbon expire in storage?

Unused activated carbon stored in sealed, dry conditions has a very long shelf life and does not “expire” quickly, but if stored open to air and humidity, pores can adsorb moisture and airborne organics, reducing available capacity at first use.

To keep activated carbon effective, it should be stored in airtight packaging away from strong odors, chemicals, and high humidity, and opened only shortly before loading into the filtration system.

5) Can activated carbon be regenerated to extend its life?

Yes, granular activated carbon can be thermally reactivated in specialized furnaces that drive off adsorbed organics and recreate internal surface area, allowing multiple reuse cycles in many industrial and municipal applications.

Gas‑phase activated carbon systems may also use on‑site regeneration with hot gas or steam for certain contaminants, which extends how long activated carbon lasts and reduces overall media consumption and waste.

Citations:

1. https://ipsystemsusa.com/maximizing-the-lifespan-of-your-carbon-filter-a-comprehensive-guide/

2. https://www.expresswater.com/products/granular-activated-carbon-whole-house

3. https://www.freshwatersystems.com/blogs/blog/activated-carbon-filters-101

4. https://pristinewatersofteners.com/activated-carbon-water-filters-lifespan-and-when-to-replace-them/

5. https://www.calgoncarbon.com/app/uploads/Basics-of-Activated-Carbon-Calgon-Carbon-Chemical-Engineering-Magazine.pdf

6. https://www.aquaticexperts.com/pages/activated-carbon-in-your-aquarium

7. https://www.aquariumcoop.com/blogs/faqs/how-long-does-aquarium-filter-media-last

8. https://cleanawater.com.au/information-centre/how-often-do-you-need-to-replace-a-carbon-filter

9. https://ergil.com/filtration-systems/carbon-bed-filter-raw-co2-gas-treatment/

10. https://services.jacobi.net/design-selection-of-air-gas-treatment-with-industrial-filters/