Content Menu

● What Is Coconut Shell Activated Carbon?

● Why Use Coconut Shell for Activated Carbon?

● Step‑by‑Step: How Activated Carbon Is Made from Coconut Shell

>> 1. Raw Coconut Shell Selection and Preparation

>> 2. Carbonization: Converting Shells to Charcoal

>> 3. Steam Activation: Developing the Pore Structure

>> 4. Cooling, Crushing, Grinding, and Screening

>> 5. Washing, Acid Washing, and Drying

>> 6. Quality Control and Packaging

● Process Overview Diagram

● Applications of Coconut Shell Activated Carbon

● Steam vs Chemical Activation for Coconut Shell

● Key Benefits of Coconut Shell Activated Carbon

● Conclusion

● FAQ About Coconut Shell Activated Carbon

>> 1) How is coconut shell activated carbon different from coal‑based activated carbon?

>> 2) Can coconut shell activated carbon be used for drinking water treatment?

>> 3) Is steam‑activated coconut shell activated carbon environmentally friendly?

>> 4) How is the quality of coconut shell activated carbon evaluated?

>> 5) Can coconut shell activated carbon be regenerated and reused?

● Citations:

Coconut shell activated carbon is made by transforming cleaned coconut shells into highly porous activated carbon through carbonization, high‑temperature steam activation, and post‑treatment steps like washing and screening. This process creates activated carbon with enormous internal surface area, excellent hardness, and low impurities for demanding water, air, food, chemical, and pharmaceutical applications.[1][2][3]

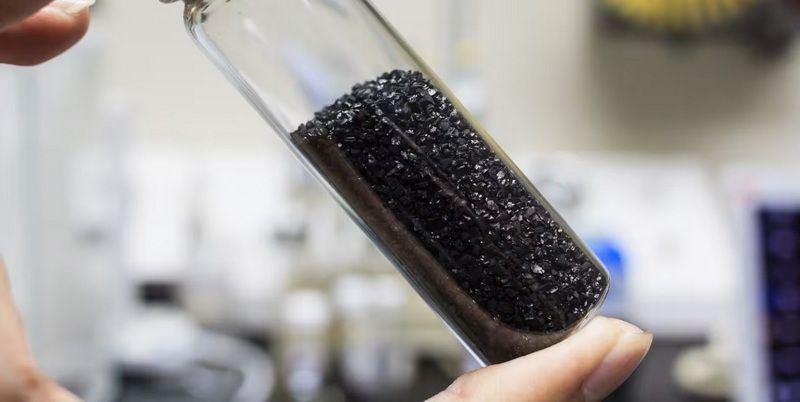

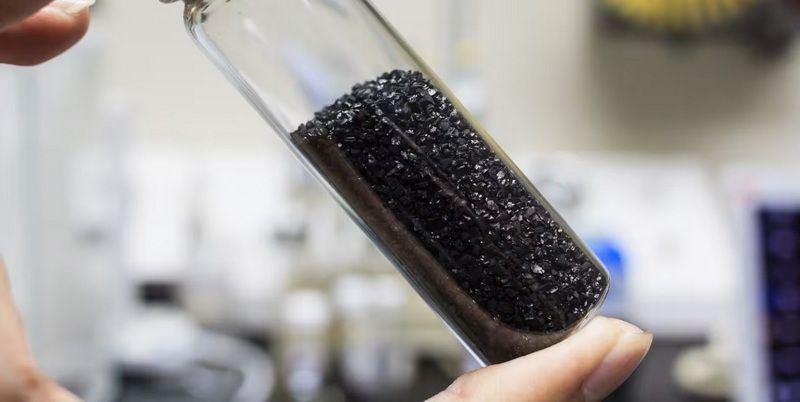

What Is Coconut Shell Activated Carbon?

Coconut shell activated carbon is a high‑performance adsorbent produced from dried coconut shells that have been carbonized and activated to create a dense network of micro‑ and mesopores. Compared with other raw materials, coconut shell activated carbon offers higher hardness, more micropores, and excellent performance in water purification, air and gas treatment, and food‑grade decolorization.[4][5][1]

- Coconut shell is an abundant, renewable agricultural by‑product that can be converted into value‑added activated carbon instead of being discarded as waste.[6][7]

- The resulting activated carbon is commonly used in granular, powdered, and pellet forms for industrial, municipal, and household filtration systems.[2][8]

Why Use Coconut Shell for Activated Carbon?

Coconut shell is considered one of the best raw materials for producing high‑quality activated carbon because of its structure and availability. Its dense lignocellulosic matrix produces hard, wear‑resistant activated carbon with a very high proportion of micropores, ideal for removing small organic molecules and trace contaminants.[10][5][1]

- Coconut shell activated carbon generally shows high adsorption capacity, low ash content, and good regeneration behavior, which improves service life and total cost of ownership in industrial systems.[1][10]

- Because coconuts grow widely in tropical regions, coconut shell activated carbon supports sustainable resource use and reduces reliance on coal‑based activated carbon.[7][6]

Step‑by‑Step: How Activated Carbon Is Made from Coconut Shell

1. Raw Coconut Shell Selection and Preparation

Production of coconut shell activated carbon begins with careful selection of mature, hard coconut shells with low moisture and minimal contamination. Shells are cleaned to remove residual coconut meat, fibers, soil, and other impurities, then dried and crushed to a controlled particle size suitable for carbonization.[11][2][7]

- Typical pre‑treatment includes washing, sun‑ or oven‑drying, and mechanical crushing or jaw‑crushing down to pieces around 50–100 mm or smaller, depending on the carbonization equipment.[2][1]

- Consistent raw material size and moisture content help ensure uniform carbonization and stable quality of the final activated carbon.[11][10]

2. Carbonization: Converting Shells to Charcoal

Carbonization transforms dried coconut shells into a carbon‑rich char by heating in limited oxygen at elevated temperatures. In this stage, volatile components and tars are driven off, leaving a solid coconut shell charcoal that will later be converted into activated carbon.[10][1][2]

- Industrial carbonization of coconut shells is typically carried out in rotary kilns, drum kilns, or other furnaces at about 400–600 °C for several hours under controlled oxygen supply.[1][2]

- Proper temperature control and residence time are critical to achieving high carbon content and yield while avoiding excessive burning or under‑carbonization of the char.[11][10]

3. Steam Activation: Developing the Pore Structure

The defining step in producing coconut shell activated carbon is steam activation of the char at very high temperatures. During activation, superheated steam reacts with the carbon, selectively burning away parts of the structure and enlarging internal pores, turning the char into highly porous activated carbon.[13][14][15][1]

- Industrial steam activation of coconut shell charcoal is usually performed at 800–1100 °C in rotary kilns or fluidized bed reactors under controlled atmosphere.[14][1]

- Steam flow rate, activation temperature, and residence time are carefully adjusted because they significantly affect pore volume, specific surface area, and adsorption capacity of the activated carbon.[15][10]

4. Cooling, Crushing, Grinding, and Screening

After steam activation, the hot coconut shell activated carbon is cooled safely, then processed to achieve the required particle sizes. Depending on the target product, the activated carbon is crushed, ground, and sieved or shaped into granular, powdered, or pellet forms.[8][2]

- Common granular coconut shell activated carbon sizes include 6–12 mesh, 8–16 mesh, 10–24 mesh, and 20–40 mesh, while finer powdered grades may be produced at 200 mesh or even 325 mesh.[2][8]

- Consistent particle size distribution improves flow properties, pressure drop behavior, and adsorption performance in filters, packed beds, and columns using coconut shell activated carbon.[8][11]

5. Washing, Acid Washing, and Drying

Many producers apply post‑treatment steps such as washing or acid washing to upgrade the quality of coconut shell activated carbon. Washing removes residual ash, fines, and soluble impurities, while acid washing can reduce heavy metals, mineral content, and water‑soluble inorganic compounds in the activated carbon.[3][2]

- A typical acid washing process uses dilute hydrochloric acid in a dedicated tank to treat coconut shell activated carbon, followed by extensive rinsing until the pH is within a target range, often about 5–7.[3][2]

- After washing, coconut shell activated carbon is dried until moisture content meets specification, often around 10 % or as requested by customers.[3][2]

6. Quality Control and Packaging

Before shipment, coconut shell activated carbon undergoes strict testing to ensure it meets the required performance and safety standards for particular applications. Typical tests include iodine number, methylene blue value, surface area (BET), hardness, ash content, moisture, pH, density, and particle size distribution for the activated carbon.[5][10]

- Once the coconut shell activated carbon passes inspection, it is packaged in moisture‑resistant bags, big bags, or bulk containers, often lined with PE to protect against humidity and contamination during transport.[7][11]

- Traceable labels and lot numbers help industrial users track each batch of coconut shell activated carbon for regulatory and quality management requirements.[10][7]

Process Overview Diagram

The full coconut shell activated carbon manufacturing process can be summarized as a continuous, controlled production flow. Each stage is optimized to maximize yield, pore development, and stability of the final activated carbon product for industrial applications.[1][2][11][10]

Applications of Coconut Shell Activated Carbon

Coconut shell activated carbon is widely used across multiple industries that require high‑purity adsorption solutions. Its microporous structure and high hardness make coconut shell activated carbon especially suitable for water treatment, air purification, and high‑specification food and pharmaceutical applications.[5][7][1][3]

- In water treatment, coconut shell activated carbon efficiently removes organic contaminants, chlorine, taste and odor compounds, and trace chemicals from drinking water, process water, and wastewater.[5][7]

- In air and gas purification, coconut shell activated carbon helps control VOCs, odors, and industrial emissions, and can also be impregnated for special gas‑phase applications.[7][1]

Steam vs Chemical Activation for Coconut Shell

Both steam activation and chemical activation can be used to produce activated carbon from coconut shell, but industrial producers often favor steam activation for large‑scale production. Chemical activation uses impregnating agents like phosphoric acid or zinc chloride, while steam activation relies on high‑temperature steam in the absence of oxygen to develop the pore structure of the activated carbon.[12][13][1]

| Aspect | Steam‑Activated Coconut Shell Activated Carbon | Chemically Activated Coconut Shell Activated Carbon |

| Activating agent | Steam, CO₂, flue gas.iarjset+1 | Phosphoric acid, ZnCl₂, other chemicals.iarjset+1 |

| Typical activation temperature | About 800–1100 °C.iarjset+2 | Often lower than steam activation.iarjset+1 |

| Main advantages | High purity, very low residual chemicals, suitable for potable water and food uses.generalcarbon+1 | Strong pore development at lower temperatures, useful for laboratory or specialty activated carbon.iarjset+1 |

| Environmental considerations | Fewer chemical wastes, focus on energy and emissions from kilns.scholarcommons.scu+1 | Requires safe handling and disposal or recovery of activation chemicals.rajahfiltertechnics+1 |

- For drinking water and food‑grade uses, steam‑activated coconut shell activated carbon is widely preferred because it avoids chemical residues in the activated carbon.[5][3]

- Chemical activation is more common in research, small‑scale production, or for tailored pore structures in specialty activated carbon grades.[1][5]

Key Benefits of Coconut Shell Activated Carbon

Coconut shell activated carbon offers a combination of performance, sustainability, and cost‑effectiveness that makes it attractive to industrial buyers and system designers. When correctly produced and specified, coconut shell activated carbon delivers high adsorption capacity, low dust, and reliable performance in continuous systems.[10][7][5][1]

- High microporosity enables coconut shell activated carbon to effectively remove low‑molecular‑weight organic compounds and trace pollutants from water and air.[10][5]

- Excellent hardness and abrasion resistance reduce dusting and loss of activated carbon during transport, handling, and backwashing operations.[7][1]

Conclusion

Coconut shell activated carbon is produced through a carefully controlled series of steps that transform waste coconut shells into a high‑value filtration material for global industries. By optimizing shell preparation, carbonization, steam activation, post‑washing, and quality control, manufacturers can deliver coconut shell activated carbon with high surface area, strong microporosity, and reliable performance for water treatment, air and gas purification, food and beverage processing, chemical production, and pharmaceutical operations. For buyers seeking sustainable, high‑efficiency filtration solutions, coconut shell activated carbon remains one of the most attractive and versatile options available today.[6][2][3][5][7][1]

FAQ About Coconut Shell Activated Carbon

1) How is coconut shell activated carbon different from coal‑based activated carbon?

Coconut shell activated carbon typically has a higher proportion of micropores than many coal‑based activated carbon products, making it especially effective for removing small organic molecules and trace contaminants. Coal‑based activated carbon often offers more mesopores and macropores, which can be advantageous for larger molecules but may have higher ash content and lower hardness compared with high‑quality coconut shell activated carbon.[5][1][10]

2) Can coconut shell activated carbon be used for drinking water treatment?

Yes, coconut shell activated carbon is widely used in municipal and household drinking water filters because of its high adsorption capacity and low level of impurities. When properly manufactured and, if necessary, acid‑washed, coconut shell activated carbon can meet stringent drinking water and food‑contact standards.[3][7][5]

3) Is steam‑activated coconut shell activated carbon environmentally friendly?

Steam‑activated coconut shell activated carbon is considered relatively environmentally friendly because it uses renewable coconut shells and avoids large‑scale chemical reagents during activation. Environmental performance still depends on furnace energy efficiency and emission controls, but using agricultural by‑products to produce activated carbon reduces waste and reliance on fossil‑based raw materials.[6][7]

4) How is the quality of coconut shell activated carbon evaluated?

Quality of coconut shell activated carbon is usually evaluated using metrics such as iodine number, methylene blue value, BET surface area, ash content, hardness, moisture, pH, and particle size distribution. Industrial buyers often specify these parameters to ensure the coconut shell activated carbon meets the adsorption performance and mechanical strength required for their systems.[7][10][5]

5) Can coconut shell activated carbon be regenerated and reused?

In many gas‑phase and some liquid‑phase applications, spent coconut shell activated carbon can be thermally regenerated to restore much of its adsorption capacity. Regeneration conditions and success depend on the type of contaminants adsorbed, but properly regenerated coconut shell activated carbon can significantly reduce operating costs and waste generation.[10][5][7]

Citations:

[1](https://iarjset.com/wp-content/uploads/2022/05/IARJSET.2022.9440.pdf)

[2](https://rotarykilnsupplier.com/activated-carbon-making/how-to-make-activated-charcoal-from-coconut-shell/)

[3](https://generalcarbon.com/facts-about-activated-carbon/a-guide-to-acid-washed-coconut-shell-activated-carbon/)

[4](https://www.sciencedirect.com/science/article/pii/S2211715622000108)

[5](https://www.sciencedirect.com/science/article/abs/pii/S096085241000444X)

[6](https://scholarcommons.scu.edu/ceng/3/)

[7](https://www.suneetacarbons.com/blog/transforming-waste-into-value-the-process-of-coconut-shell-activated-carbon/)

[8](https://rotarykilnfactory.com/how-to-make-activated-carbon-from-coconut-shell/)

[9](https://www.youtube.com/watch?v=LmWb7JbW5Gs)

[10](https://www.agriculturaljournals.com/archives/2024/vol6issue1/PartA/5-2-34-245.pdf)

[11](https://gycarbons.com/News/70.html)

[12](https://rajahfiltertechnics.com/water-filtration/coconut-becomes-activated-carbon/)

[13](https://blackicepatch.com/blogs/news/how-to-make-steam-activated-charcoal)

[14](https://www.intratec.us/solutions/commodity-production-costs/reports/activated-carbon-production-cost-activated-carbon-production-from-coconut-shell-steam-activation)

[15](https://www.huameicarbon.com/what-exactly-is-steam-activated-coconut-shell-carbon/)