Content Menu

● What Is Activated Carbon?

● How Does Activated Carbon Filter Water?

● Pore Structure and Surface Area

● Key Contaminants Removed by Activated Carbon

● Main Types of Activated Carbon Filters

>> Common Filter Types

● Raw Materials for Activated Carbon

● Operating Principles of an Activated Carbon Filter

● Advantages of Activated Carbon in Water Treatment

● Limitations and When to Combine Technologies

● Maintenance and Service Life of Activated Carbon Filters

● Industrial and Municipal Uses of Activated Carbon

● How Activated Carbon Supports Safe Drinking Water

● Conclusion

● FAQ

>> 1. How exactly does activated carbon remove contaminants from water?

>> 2. What contaminants can activated carbon filters remove?

>> 3. How long does an activated carbon water filter last?

>> 4. Is activated carbon safe for drinking water applications?

>> 5. What is the difference between GAC and carbon block activated carbon filters?

● Citations:

“How Does Activated Carbon Filter Water” is a question that leads directly to the science of adsorption, pore structure, and contact time in modern water treatment. Activated carbon filters water by adsorbing contaminants onto a vast internal surface area, removing chlorine, organic chemicals, taste, odor, and a wide range of micropollutants from drinking and process water.[1][2]

What Is Activated Carbon?

Activated carbon is a specially processed form of carbon with an extremely high internal surface area and a network of microscopic pores that can trap dissolved and suspended contaminants from water. This porous “sponge‑like” material is usually produced from carbon‑rich raw materials such as coal, wood, or coconut shells, then “activated” at high temperatures with steam or gases to create the pore structure.[3][4][5]

In many water filtration systems, activated carbon appears as granular activated carbon (GAC) or as a compressed carbon block, both designed to maximize contact between water and the carbon surface. One gram of high‑quality activated carbon can provide thousands of square meters of internal surface area, which explains its exceptional adsorption capacity in water treatment.[2][6][4][1]

How Does Activated Carbon Filter Water?

Activated carbon filters water primarily through adsorption, a process in which molecules in the water are attracted to and held on the internal surfaces of the carbon pores by physical and chemical forces. As water flows through a bed or block of activated carbon, contaminants such as chlorine, volatile organic compounds (VOCs), and many organic chemicals diffuse into the pores and adhere to the carbon surface.[7][8][1][2]

The driving forces include van der Waals forces, hydrophobic interactions, and sometimes specific chemical interactions between functional groups on the activated carbon and the contaminant molecules. Over time, the available sites on the activated carbon fill up, and the filter approaches “breakthrough,” at which point spent activated carbon must be replaced or thermally regenerated to restore filtration performance.[9][3][2]

Pore Structure and Surface Area

The effectiveness of activated carbon in water filtration depends heavily on its pore size distribution and total surface area. Activation creates micro‑, meso‑, and macropores; micropores (less than 2 nanometers) are particularly important for adsorbing small organic molecules and many trace contaminants.[4][3][2]

A larger internal surface area gives activated carbon more active sites where contaminants can attach, improving both capacity and removal efficiency. Steam activation of suitable raw materials often produces highly microporous activated carbon, which is especially useful when targeting low concentrations of organic pollutants or disinfection by‑products in drinking water.[10][3][2][4]

Key Contaminants Removed by Activated Carbon

Activated carbon is widely used to remove chlorine and chloramine from municipal water, protecting downstream membranes and improving taste and odor. It also adsorbs many organic chemicals, including VOCs, pesticides, herbicides, industrial solvents, and other taste‑ and odor‑forming compounds in drinking water and process water.[11][12][13][2]

In advanced treatment, high‑quality granular activated carbon can also reduce certain heavy metals and modern contaminants like some per‑ and polyfluoroalkyl substances (PFAS), especially when properly designed and maintained. However, not all inorganic ions are efficiently removed by activated carbon, which is why it is often combined with other technologies such as reverse osmosis, ion exchange, or UV disinfection.[12][6][14][13]

Main Types of Activated Carbon Filters

Different activated carbon formats are optimized for specific water treatment tasks and system designs. The three most widely used types in water filtration are granular activated carbon (GAC), carbon block filters, and powdered activated carbon (PAC).[6][1]

Common Filter Types

| Filter type | Description | Typical applications |

| Granular activated carbon (GAC) | Loose granules of activated carbon in a cartridge or fixed bed; offers high flow rates and easy regeneration or replacement.freshwatersystems+1 | Whole‑house filters, industrial process water, municipal polishing. |

| Carbon block | Densely compressed activated carbon forming a solid block with controlled porosity and longer contact time.freshwatersystems+1 | Point‑of‑use drinking water systems, refrigerator filters, under‑sink filters. |

| Powdered activated carbon (PAC) | Fine powdered activated carbon dosed into water and later removed by clarification or filtration.cropaia+1 | Municipal plants for taste and odor control, seasonal pollution events, wastewater polishing. |

GAC beds provide continuous treatment and can be thermally reactivated, making them economical for large‑scale water treatment and industrial systems. Carbon block filters, in contrast, are very effective at polishing drinking water in compact devices, where consistent flow and high removal of chlorine and organics are needed at the tap.[14][1][6][9]

Raw Materials for Activated Carbon

Activated carbon can be manufactured from several carbon‑rich raw materials, each with distinct properties that influence performance in water filtration. Coal‑based activated carbon offers strong mechanical strength and high microporosity, making it suitable for robust industrial and municipal systems.[5][15][3]

Coconut shell–based activated carbon is popular in drinking water filters because of its dense microporous structure, renewable origin, and excellent adsorption of small organic molecules and chlorine. Wood‑based activated carbon can provide a larger proportion of mesopores, which can be advantageous in certain applications involving larger molecules or color bodies.[15][5][10]

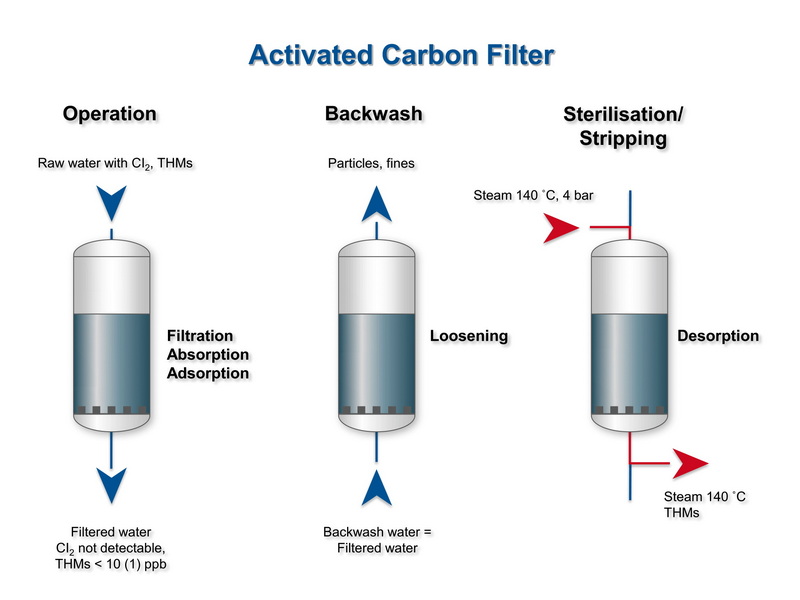

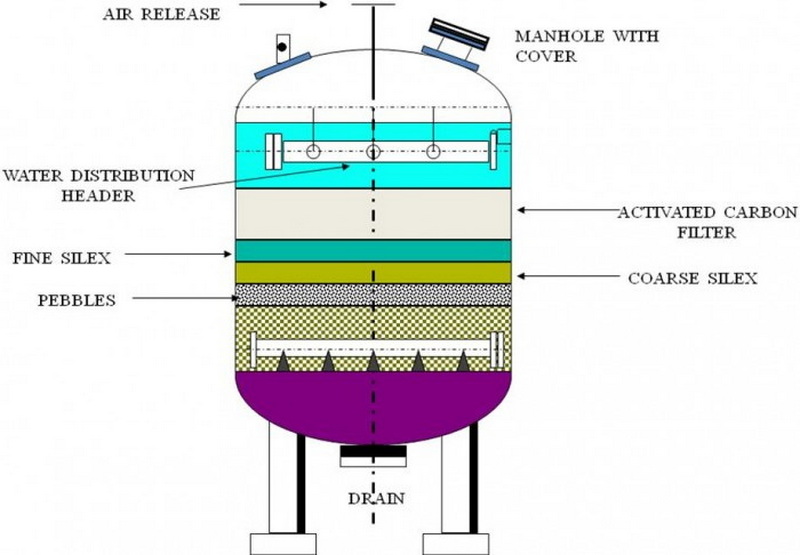

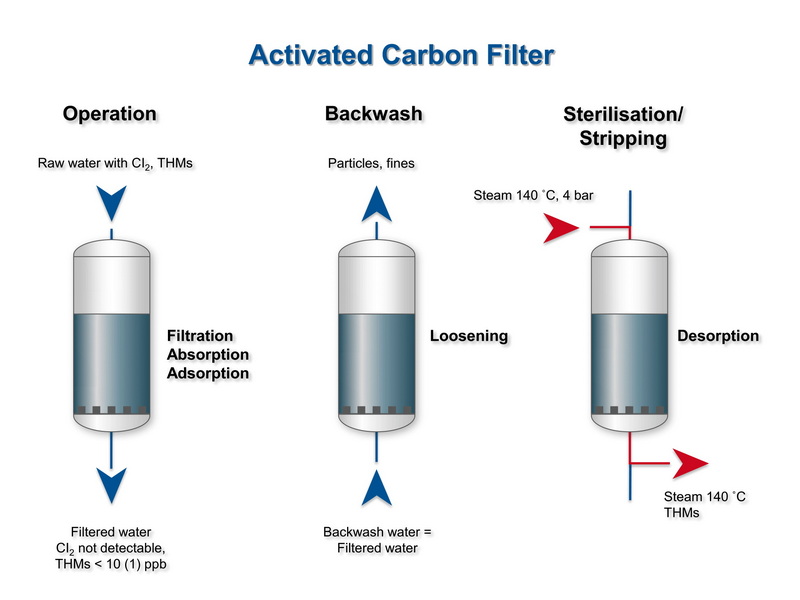

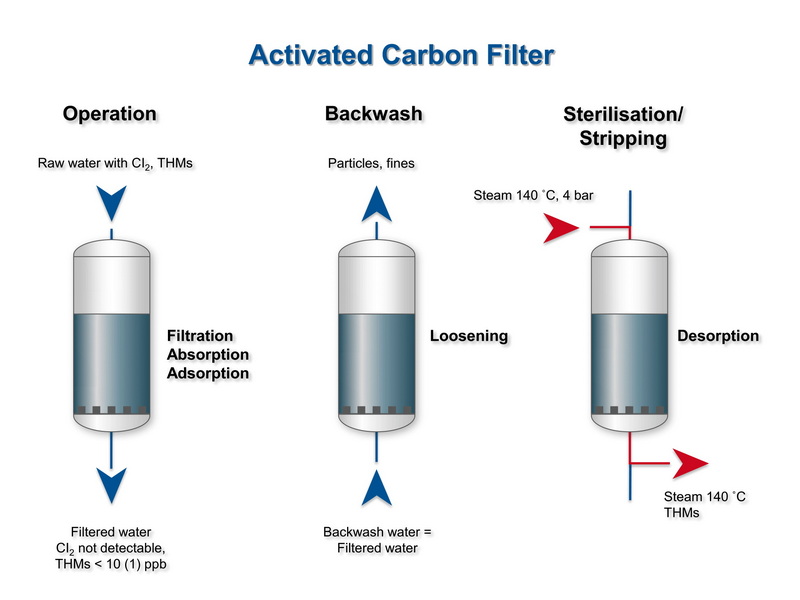

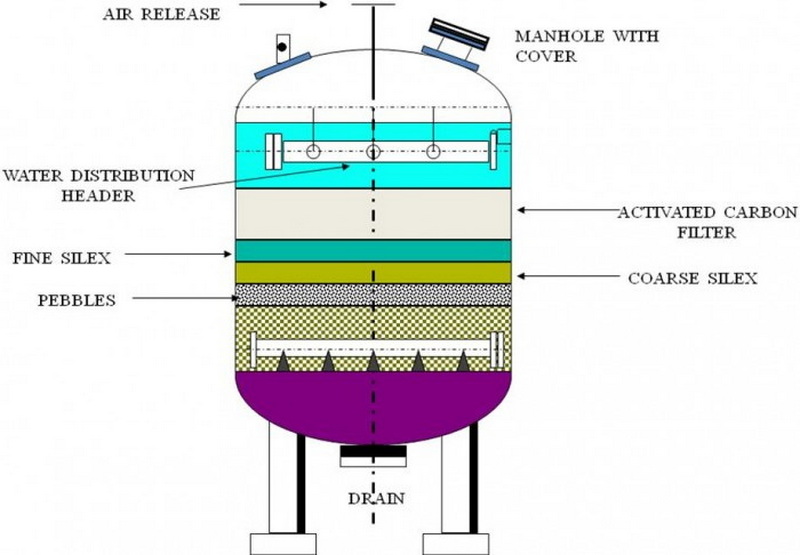

Operating Principles of an Activated Carbon Filter

Inside an activated carbon filter, water flows through a packed bed or block of activated carbon at a controlled rate to ensure adequate contact time. As the water moves through the activated carbon, contaminants diffuse into the pores and are retained on the internal surfaces, while treated water exits with reduced levels of target pollutants.[8][1][2][4]

Key design factors include bed depth, flow rate, contact time, and the quality and type of activated carbon selected. Longer contact time and properly sized activated carbon beds generally improve adsorption performance, but systems must also balance pressure drop, flow demand, and media replacement intervals for practical operation.[2][12][8]

Advantages of Activated Carbon in Water Treatment

Activated carbon offers several important advantages that explain its widespread use in residential, commercial, and industrial water treatment.[12][10]

- It effectively removes chlorine and many organic contaminants, improving taste, odor, and safety of potable water.[16][11]

- It can protect downstream equipment, such as reverse osmosis membranes and ion exchange resins, by removing oxidants and organic foulants.[13][12]

- Granular activated carbon can be reactivated through controlled thermal processes, providing a more sustainable and cost‑effective solution for large‑scale systems.[9][14]

In addition, activated carbon is a versatile medium that can be tailored through raw material selection, activation method, and particle size for different water qualities and system designs. This flexibility allows activated carbon to serve in applications ranging from household filters and beverage production to pharmaceutical water and wastewater polishing.[3][5][14][12]

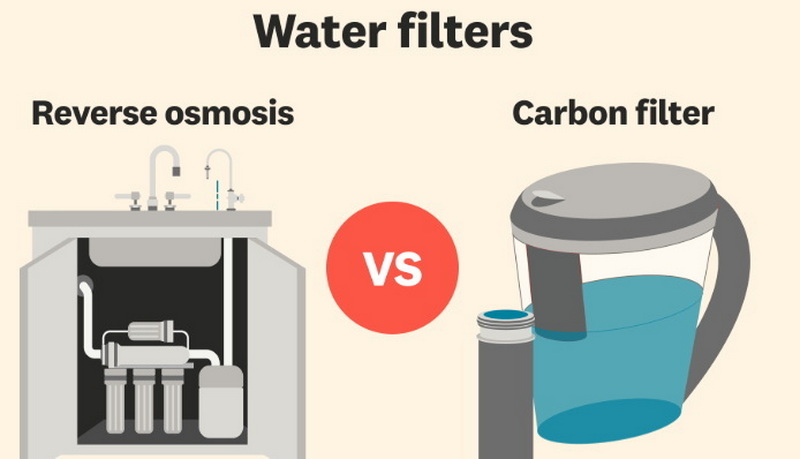

Limitations and When to Combine Technologies

Although activated carbon is highly effective for many contaminants, it does not remove all impurities from water. Dissolved inorganic salts, hardness ions, and many simple minerals pass through activated carbon, which is why it is often combined with reverse osmosis, ion exchange, or other physical and chemical treatment processes.[17][13][12]

Some contaminants, such as certain PFAS species and highly soluble small molecules, may require optimized activated carbon types, higher bed volumes, or complementary technologies to achieve regulatory targets. Proper system engineering, including pilot testing and monitoring, is essential to understand how a specific activated carbon product will perform on a real water source.[14][10]

Maintenance and Service Life of Activated Carbon Filters

The service life of an activated carbon filter depends on contaminant loading, water quality, flow rate, and the specific capacity of the activated carbon used. As adsorption sites become saturated, contaminants begin to appear at the outlet, signaling breakthrough and the need for replacement or regeneration of the activated carbon media.[8][2][9]

For small domestic activated carbon filters, cartridges are replaced at fixed time or volume intervals recommended by the manufacturer, while large industrial GAC filters may be serviced by removing spent activated carbon for thermal reactivation and refilling with fresh or regenerated media. Regular monitoring of water quality and pressure drop helps ensure that the activated carbon continues to filter water effectively and safely.[17][9][8][14]

Industrial and Municipal Uses of Activated Carbon

In municipal drinking water plants, activated carbon is used to control taste and odor, remove organic chemicals, and protect other treatment stages. Utilities may feed powdered activated carbon during episodes of algal blooms or industrial contamination, and operate large granular activated carbon contactors for continuous polishing of finished water.[12][9][17]

Industrial facilities rely on activated carbon filters for process water, product quality, and wastewater treatment, especially in sectors such as food and beverage, chemical manufacturing, and pharmaceuticals. In laboratory and high‑purity water systems, activated carbon is used as a pretreatment step to remove chlorine, chloramines, and trace organics before fine membrane treatment and polishing.[13][10][14]

How Activated Carbon Supports Safe Drinking Water

For consumers, one of the most visible roles of activated carbon is in point‑of‑use drinking water systems, pitchers, countertop filters, and refrigerator cartridges. In these applications, compact activated carbon cartridges reduce chlorine, off‑tastes, and odors, and many designs also target lead, volatile organic compounds, and other harmful compounds to improve overall drinking water quality.[18][1][6]

At the municipal level, large‑scale activated carbon treatment helps utilities comply with regulations on disinfection by‑products and organic contaminants, while enhancing consumer confidence in tap water. Together, these uses show how activated carbon has become a central technology for delivering cleaner, safer, and better‑tasting water worldwide.[14][12]

Conclusion

Activated carbon filters water through adsorption on a vast internal surface area, capturing chlorine, many organic chemicals, taste‑ and odor‑forming compounds, and a range of emerging pollutants as water passes through its pores. Different formats of activated carbon—such as granular activated carbon, carbon block, and powdered activated carbon—allow the technology to serve in household filters, municipal treatment plants, and industrial systems across drinking water, food and beverage, chemical, and pharmaceutical applications.[1][6][2][12]

While activated carbon does not remove all dissolved substances, it is a powerful and versatile medium that can be combined with other technologies, carefully selected raw materials, and proper system design to deliver reliable, high‑quality water treatment for global users.[13][12]

FAQ

1. How exactly does activated carbon remove contaminants from water?

Activated carbon removes contaminants mainly by adsorption, where molecules in the water are attracted to and held on the internal surfaces inside the carbon pores. Physical forces and, in some cases, specific chemical interactions cause chlorine, VOCs, and many organics to attach to the activated carbon until its available sites are filled.[7][4][3][2]

2. What contaminants can activated carbon filters remove?

Activated carbon filters effectively remove chlorine, many disinfection‑by‑products, volatile organic compounds, pesticides, herbicides, and various taste‑ and odor‑forming substances. Certain formulations and designs of activated carbon can also reduce some heavy metals and PFAS species, although not all inorganic ions are removed, so complementary treatment may still be required.[11][6][2][14]

3. How long does an activated carbon water filter last?

The life of an activated carbon filter depends on water quality, contaminant load, flow rate, and the capacity of the activated carbon media. When adsorption sites become saturated, breakthrough occurs and the activated carbon must be replaced or regenerated, which for household filters typically means following the manufacturer's recommended time or volume guidelines.[2][9][8]

4. Is activated carbon safe for drinking water applications?

High‑quality activated carbon manufactured for potable water use is considered safe and is widely used in certified drinking water filtration products and municipal systems. The activated carbon itself is not consumed; instead, it simply adsorbs contaminants as water passes through, provided the system is properly designed and maintained according to applicable standards.[16][11][1][8]

5. What is the difference between GAC and carbon block activated carbon filters?

Granular activated carbon (GAC) filters use loose activated carbon granules, allowing higher flow rates and easy media replacement, which suits whole‑house and industrial systems. Carbon block activated carbon filters compress the media into a solid block, providing longer contact time and higher removal efficiency for many drinking water contaminants in compact, point‑of‑use devices.[6][1][9]

Citations:

[1](https://www.freshwatersystems.com/blogs/blog/activated-carbon-filters-101)

[2](https://www.cleantechwater.co.in/blog/need-know-activated-carbon-filter-works/)

[3](https://www.rbhltd.com/market-news/activated-carbon-for-water-filtration-how-does-it-work/)

[4](https://en.wikipedia.org/wiki/Carbon_filtering)

[5](https://rajahfiltertechnics.com/water-filtration/choosing-activated-carbon-filter/)

[6](https://www.osmotics.co.uk/blog/post/main-carbon-filter-types-water-filtration-guide)

[7](https://carbonblocktech.com/the-science-behind-activated-carbon-water-filters/)

[8](https://www.health.state.mn.us/communities/environment/hazardous/topics/gac.html)

[9](https://enva.com/case-studies/activated-carbon-in-water-treatment)

[10](https://sodimate-inc.com/activated-carbon-types-applications-advantages/)

[11](https://extensionpubs.unl.edu/publication/g1489/na/pdf/view)

[12](https://cropaia.com/blog/activated-carbon-in-water-treatment/)

[13](https://us.elgalabwater.com/activated-carbon)

[14](https://www.calgoncarbon.com/municipal-water-treatment/)

[15](https://carbonblocktech.com/coconut-wood-coal-filters/)

[16](https://espwaterproducts.com/pages/carbon-filters)

[17](https://www.ncbi.nlm.nih.gov/books/NBK234593/)

[18](https://swiftgreenfilters.com/blogs/water-filters/what-are-the-types-of-activated-carbon)

[19](https://www.youtube.com/watch?v=WGnktQm_ttE)

[20](https://puragen.com/uk/insights/how-does-activated-carbon-filter-water/)