Content Menu

● What Is Activated Carbon Adsorption

● Physisorption And Chemisorption On Activated Carbon

● Role Of Pore Size And Surface Area

● Adsorption Isotherms And Capacity Of Activated Carbon

● Factors That Influence Activated Carbon Adsorption

● How Activated Carbon Adsorption Works In Water Treatment

● How Activated Carbon Adsorption Works In Air And Gas Treatment

● Surface Chemistry And Modified Activated Carbon

● Regeneration And Life Cycle Of Activated Carbon Adsorption

● Conclusion

● FAQ – Activated Carbon Adsorption

>> (1) How does activated carbon adsorption differ from absorption?

>> (2) Why does activated carbon have such a high adsorption capacity?

>> (3) What is an adsorption isotherm in activated carbon design?

>> (4) How do temperature and concentration affect activated carbon adsorption?

>> (5) Can activated carbon be regenerated after adsorption?

● Citations:

Activated carbon adsorption works by capturing molecules from water, air, and process streams onto the huge internal surface area of a porous activated carbon structure. In industrial and household systems, activated carbon adsorption is one of the most widely used technologies for removing organic pollutants, chlorine, odors, colors, and many trace chemicals.[1][2][3]

What Is Activated Carbon Adsorption

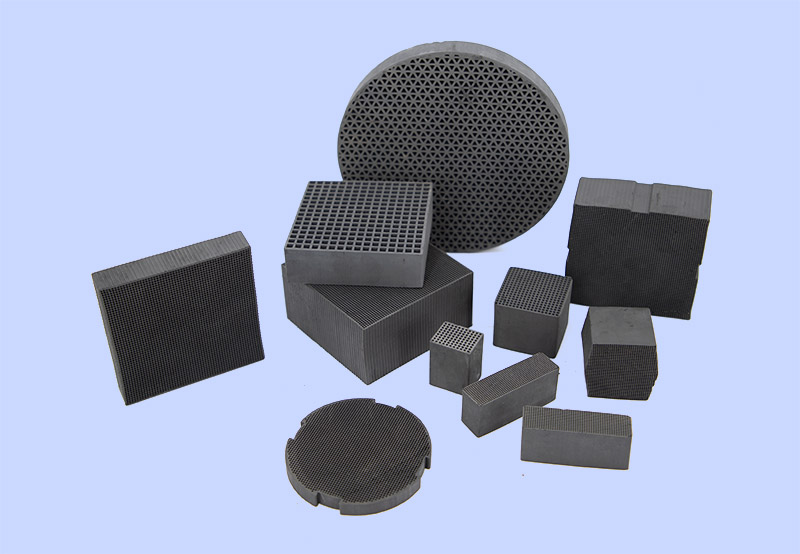

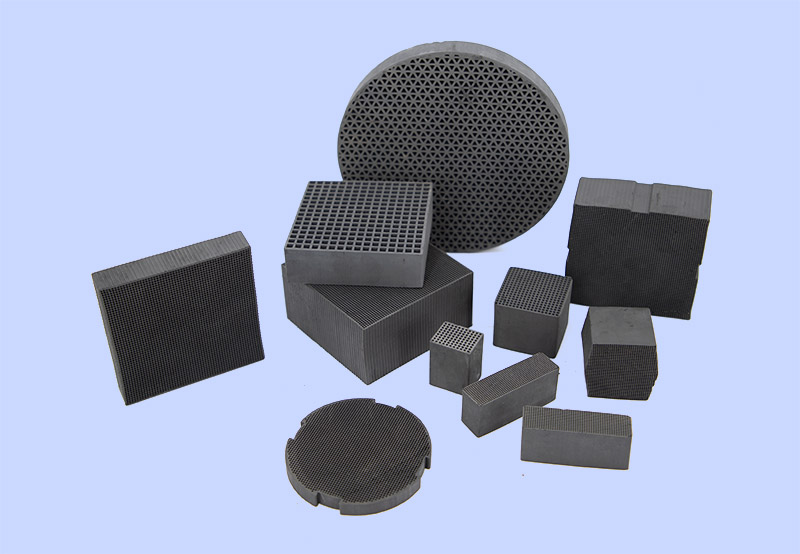

Activated carbon is a specially processed carbon material with an extremely large internal surface area and a network of micropores, mesopores, and macropores that provide countless adsorption sites. In adsorption, molecules from a fluid phase accumulate on the surface of activated carbon and are held there by physical or chemical forces instead of dissolving into the bulk of the carbon.[2][3][4][5]

- A small amount of activated carbon can have more surface area than a football field, giving it very high adsorption capacity.[6][3]

- The pore size distribution of activated carbon strongly influences which contaminants can enter the pores and be adsorbed efficiently.[7][3]

Physisorption And Chemisorption On Activated Carbon

Activated carbon adsorption occurs mainly through two mechanisms: physisorption and chemisorption. Physisorption is driven by weak van der Waals forces between the activated carbon surface and the contaminant molecules, while chemisorption involves the formation of stronger chemical bonds.[8][9][10]

- In physisorption, adsorption energies are relatively low and the process is reversible, so the activated carbon can often be thermally regenerated and used for multiple cycles.[9][8]

- In chemisorption, contaminant molecules react with functional groups on the activated carbon surface, creating stronger, often more permanent bonds that are harder to desorb.[10][8]

Role Of Pore Size And Surface Area

The adsorption capacity of activated carbon is controlled by its specific surface area and pore size distribution. Micropores provide most of the surface area for adsorption, while mesopores and macropores facilitate transport of adsorbate molecules into the internal structure of the activated carbon.[3][5][7]

- Micropores, typically below about 2 nm, dominate the adsorption of small molecules and gases on activated carbon.[5][7]

- Mesopores and larger pores in activated carbon improve diffusion rates and help larger organic molecules reach the internal adsorption sites.[7][3]

Adsorption Isotherms And Capacity Of Activated Carbon

Adsorption isotherms describe how much of a given contaminant an activated carbon can adsorb at equilibrium as a function of its concentration at a constant temperature. Common isotherm models used to characterize activated carbon adsorption include Langmuir, Tóth, and Dubinin–Astakhov equations.[11][12]

- Isotherm models provide parameters such as maximum adsorption capacity and affinity, which are essential for sizing industrial activated carbon adsorption systems.[12][11]

- Experimental isotherm data for gases like carbon dioxide on activated carbon show that adsorption capacity depends strongly on temperature and pressure.[11][5]

Factors That Influence Activated Carbon Adsorption

Many practical factors affect how activated carbon adsorption performs in real systems, including contaminant properties, operating conditions, and carbon characteristics.[13][1][2]

- Higher inflow contaminant concentration and greater structural complexity of molecules generally increase the loading on activated carbon up to its capacity limit.[14][1]

- Adsorption capacity on activated carbon typically decreases at higher temperatures and can be influenced by the presence of competing species in the fluid.[1][8]

How Activated Carbon Adsorption Works In Water Treatment

In water treatment, activated carbon adsorption is used to remove organic contaminants, chlorine, taste and odor compounds, color, and many trace chemicals. Granular activated carbon beds often operate as fixed‑bed adsorbers, where water passes through a packed column and contaminants are removed as they diffuse into and adsorb onto the activated carbon particles.[6][13][2]

- Activated carbon adsorption in water plants may be used as powdered activated carbon dosed into basins or as granular activated carbon filters downstream of clarification and filtration.[13][6]

- Breakthrough curves are monitored to determine when the activated carbon bed is exhausted and needs to be replaced or thermally reactivated.[13][11]

How Activated Carbon Adsorption Works In Air And Gas Treatment

In air and gas purification, activated carbon adsorption is widely used to capture volatile organic compounds and odorous components by transferring them from the gas stream to the solid carbon surface. Packed beds of activated carbon or modular cartridges are placed in exhaust lines to comply with emission regulations and improve occupational and environmental air quality.[4][2][10]

- For industrial emissions, activated carbon adsorption systems are designed for sufficient residence time and bed depth so that VOCs and odors are effectively removed before discharge.[2][10]

- In indoor air cleaners, activated carbon filters are often combined with particulate filters to remove both particles and gaseous pollutants.[4][10]

Surface Chemistry And Modified Activated Carbon

The surface chemistry of activated carbon, including oxygen‑containing functional groups and impregnated additives, can be tailored to improve adsorption of specific contaminants. Surface modification of activated carbon can enhance chemisorption, increase affinity for polar compounds, or promote catalytic reactions on the carbon surface.[15][14][8]

- For certain metals or reactive gases, impregnated activated carbon provides higher selectivity and stronger chemisorption than unmodified carbon.[14][8]

- Functional groups on activated carbon surfaces can participate in specific interactions with adsorbate molecules, such as forming strong bonds with dye molecules in solution.[15][14]

Regeneration And Life Cycle Of Activated Carbon Adsorption

Once activated carbon becomes saturated with contaminants, adsorption capacity drops and the media must be replaced or regenerated. Thermal reactivation of activated carbon drives off adsorbed species and partially restores the pore structure, allowing the activated carbon to be reused in industrial systems.[11][13]

- Regeneration strategies for activated carbon depend on the type of adsorbed contaminants, local regulations, and economic considerations.[13][11]

- The reversibility of physisorption on activated carbon supports multiple adsorption–desorption cycles, while chemisorbed contaminants may require higher temperatures or cannot be fully removed.[8][9]

Conclusion

Activated carbon adsorption works by capturing contaminants from water, air, and gases on the vast internal surface area of a porous activated carbon structure through a combination of physisorption and chemisorption. By optimizing pore structure, surface chemistry, operating conditions, and regeneration strategies, activated carbon adsorption systems can deliver reliable, cost‑effective purification for municipal water, industrial processes, VOC control, and many other critical applications.[9][1][6][2]

FAQ – Activated Carbon Adsorption

(1) How does activated carbon adsorption differ from absorption?

In activated carbon adsorption, molecules accumulate on the surface of the activated carbon and are held by physical or chemical forces, rather than diffusing into the bulk of the solid. In absorption, by contrast, molecules penetrate into the volume of another phase, such as a gas dissolving into a liquid, instead of remaining primarily at a surface as in activated carbon adsorption.[12][2][4]

(2) Why does activated carbon have such a high adsorption capacity?

Activated carbon has an extremely high internal surface area because activation develops a network of micropores and mesopores, providing numerous adsorption sites. This highly porous structure allows a small mass of activated carbon to present a surface area comparable to or larger than a football field, giving very high adsorption capacity for many contaminants.[3][5][6][7]

(3) What is an adsorption isotherm in activated carbon design?

An adsorption isotherm describes the relationship between the amount of contaminant adsorbed on activated carbon and its equilibrium concentration in the fluid phase at a fixed temperature. Engineers use isotherm models such as Langmuir, Tóth, or Dubinin–Astakhov to predict how much of a given contaminant an activated carbon bed can hold and to size industrial adsorption systems.[12][11]

(4) How do temperature and concentration affect activated carbon adsorption?

For most contaminants, higher influent concentration increases the loading on activated carbon until adsorption sites approach saturation. Higher temperatures usually decrease adsorption capacity of activated carbon because thermal energy makes it easier for molecules to desorb from the surface, reducing net uptake at equilibrium.[1][11]

(5) Can activated carbon be regenerated after adsorption?

Yes, many activated carbon adsorbents can be thermally regenerated by heating to desorb physisorbed contaminants and restore a large portion of their adsorption capacity. Regeneration effectiveness depends on the nature of the adsorbed species, as strongly chemisorbed contaminants on activated carbon may require higher temperatures or may not be fully removable.[8][9][11][13]

Citations:

[1](https://www.chemviron.eu/how-does-activated-carbon-work/)

[2](https://www.epa.gov/air-emissions-monitoring-knowledge-base/monitoring-control-technique-activated-carbon-adsorber)

[3](https://pmc.ncbi.nlm.nih.gov/articles/PMC8469776/)

[4](https://aircleansystems.com/news/how-carbon-adsorption-works)

[5](https://hidenisochema.com/content/uploads/2016/04/Hiden-Isochema-Application-Note-126.pdf)

[6](https://www.watertechonline.com/wastewater/article/15549902/the-basics-of-activated-carbon-adsorption)

[7](https://pmc.ncbi.nlm.nih.gov/articles/PMC7901990/)

[8](https://pmc.ncbi.nlm.nih.gov/articles/PMC8264938/)

[9](https://urfjournals.org/open-access/activated-carbons-for-direct-air-capture-adsorption-mechanisms-material-design-and-performance-optimization.pdf)

[10](https://www.desotec.com/en/knowledge-hub/article/activated-carbon-adsorption-for-the-removal-of-industrial-odours)

[11](https://pubs.acs.org/doi/10.1021/je100973t)

[12](https://pmc.ncbi.nlm.nih.gov/articles/PMC3709070/)

[13](https://www.calgoncarbon.com/app/uploads/Basics-of-Activated-Carbon-Calgon-Carbon-Chemical-Engineering-Magazine.pdf)

[14](https://www.sciencedirect.com/science/article/pii/S0045653522002570)

[15](https://pmc.ncbi.nlm.nih.gov/articles/PMC9037662/)

[16](https://www.perplexity.ai/search/e76c6a69-d082-4afb-a415-5f01dd3a8938)