Content Menu

● How Activated Carbon Works Against PFAS

● How Effective Are Activated Carbon Filters for PFAS?

● What Factors Control PFAS Removal by Activated Carbon?

● Activated Carbon vs Other PFAS Treatment Technologies

>> Key PFAS Technologies Overview

● Industrial Uses of Activated Carbon for PFAS

● Conclusion

● FAQ: PFAS and Activated Carbon Filters

>> 1) Do all activated carbon filters remove PFAS?

>> 2) Are granular activated carbon filters better than powdered activated carbon for PFAS?

>> 3) How long do activated carbon filters last when treating PFAS?

>> 4) Is activated carbon enough to meet the strictest PFAS regulations?

>> 5) What happens to PFAS after they are captured by activated carbon?

● Citations:

Per‑ and polyfluoroalkyl substances (PFAS) are a large group of synthetic chemicals used in countless industrial and consumer products because of their oil‑ and water‑repellent properties. PFAS are nicknamed “forever chemicals” because their strong carbon‑fluorine bonds make them extremely persistent in the environment and difficult to remove from water using conventional treatment.[3][6]

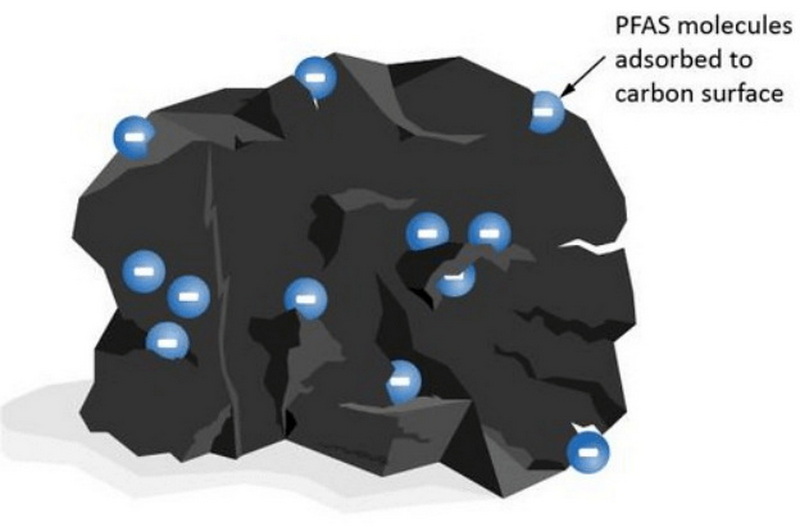

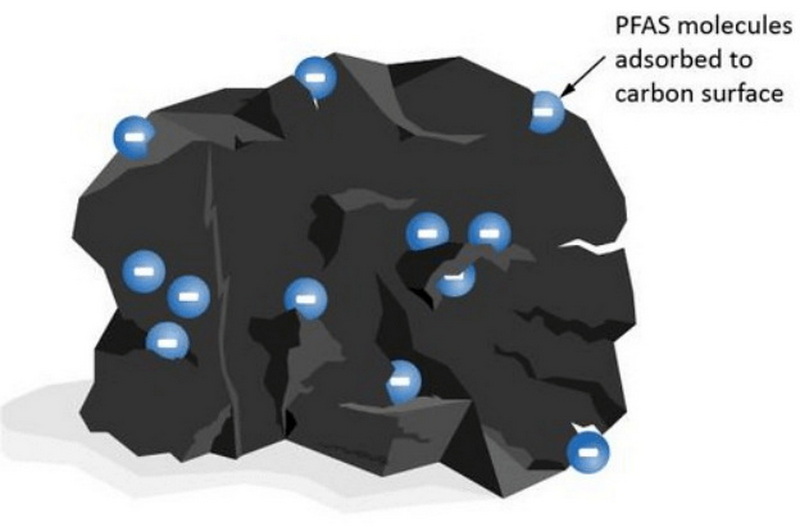

Activated carbon has become a core technology for PFAS treatment because its highly porous structure and large internal surface area allow PFAS molecules to adsorb onto the carbon surface rather than remaining dissolved in water. In both drinking water plants and industrial facilities, granular activated carbon filters are now routinely deployed to bring PFAS down to very low or even non‑detectable levels under the right conditions.[2][7][5][1]

From a practical standpoint, the question “do activated carbon filters remove PFAS?” is mostly about *how well*, *for which PFAS*, and *for how long* a given activated carbon system can maintain performance before breakthrough occurs. Understanding these details lets end users choose between different activated carbon products and design solutions tailored to their PFAS profile, flow rate, and regulatory targets.[7][6][1][2][3]

How Activated Carbon Works Against PFAS

Activated carbon is a specially processed carbonaceous material with a labyrinth of micro‑, meso‑, and macropores that create an enormous internal surface area—often hundreds to over a thousand square meters per gram. When water passes through an activated carbon bed, organic contaminants, including many PFAS molecules, adhere to this surface through physical adsorption and hydrophobic interactions.[8][5][1][2]

In PFAS treatment, granular activated carbon (GAC) beds are typically installed in fixed‑bed pressure vessels or gravity filters, allowing a controlled empty bed contact time (EBCT) to ensure sufficient interaction between PFAS and activated carbon. For short‑term events or polishing steps, powdered activated carbon (PAC) can be dosed directly into the water stream, then removed downstream via sedimentation or filtration once PFAS have adsorbed onto the activated carbon particles.[9][5][2][7]

Because activated carbon does not chemically destroy PFAS but rather concentrates them, the filter media gradually becomes saturated, and PFAS begin to “break through” into the treated water if the activated carbon is not replaced or reactivated in time. Industrial suppliers now offer specialized activated carbon reactivation processes that treat PFAS‑loaded carbon at high temperature to break down PFAS and restore adsorption capacity, enabling a more sustainable life cycle for activated carbon systems.[10][11][5][3][7]

How Effective Are Activated Carbon Filters for PFAS?

Numerous pilot‑ and full‑scale studies show that properly designed activated carbon systems can remove PFAS with high efficiency, especially long‑chain PFAS such as PFOA and PFOS. In some cases, high‑performance granular activated carbon products in optimized drinking water systems have reduced PFAS concentrations to below detection limits, demonstrating that activated carbon can meet very stringent regulatory targets.[5][1][2][3][7]

However, removal percentages vary with PFAS chain length, water chemistry, carbon type, and operating conditions. Studies report that granular activated carbon filters can achieve removal ranges of roughly 67–100% for PFAS overall, with better performance on long‑chain PFAS and earlier in the filter's service life; shorter‑chain PFAS are more difficult to capture and often break through sooner.[12][1][9][3]

For household‑scale filters, research and government health agencies note that systems containing activated carbon or reverse osmosis membranes are the most common technologies for reducing PFAS at the tap. Yet small activated carbon cartridges vary greatly in design and capacity, and some retail products do not claim PFAS reduction at all, so independent certification or performance data should always be checked before relying on a point‑of‑use activated carbon filter for PFAS control.[13][14][4][15]

What Factors Control PFAS Removal by Activated Carbon?

Several key variables determine whether an activated carbon filter will effectively remove PFAS from a specific water source.[1][13][3]

- PFAS type and chain length

- Long‑chain PFAS (typically with more than six carbon atoms), such as PFOA and PFOS, display stronger adsorption to activated carbon and are generally removed more efficiently.[16][9][2][3]

- Short‑chain PFAS are more mobile and hydrophilic, making them harder for activated carbon to capture; they often require more advanced activated carbon products, longer contact times, or complementary technologies.[6][9][3][12]

- Activated carbon type and quality

- Granular activated carbon (GAC) is the dominant media for large‑scale PFAS filtration, offering a balance between pressure drop, contact time, and ease of replacement or reactivation.[2][5][6][1]

- Powdered activated carbon (PAC) can provide rapid adsorption for emergency or seasonal PFAS spikes but typically needs higher doses and produces more sludge, making it better suited as a short‑term or supplementary solution.[9][5]

- Contact time and bed design

- Longer EBCT in a well‑designed activated carbon vessel increases the probability that PFAS molecules will adsorb, improving removal efficiency.[3][7][5]

- Lower flow rates and deeper activated carbon beds generally enhance PFAS capture, while high flow or undersized filters accelerate breakthrough and shorten the useful life of the activated carbon.[7][6][3]

- Competing contaminants and water chemistry

- Natural organic matter and other organic contaminants can compete for adsorption sites, reducing the effective capacity of activated carbon for PFAS and shortening filter life.[13][1][3]

- Parameters such as pH, temperature, and dissolved organic carbon can shift adsorption behavior, so pilot testing is often recommended before finalizing industrial activated carbon system design.[9][3][7]

Activated Carbon vs Other PFAS Treatment Technologies

Activated carbon is not the only option for PFAS removal, and it is often combined with other processes to achieve robust treatment across a broad PFAS spectrum. Ion exchange resins and membrane technologies such as reverse osmosis (RO) can sometimes provide higher removal of short‑chain PFAS, but they come with different cost, energy, and waste management trade‑offs compared with activated carbon.[17][11][6][1][3]

Key PFAS Technologies Overview

| Technology | Primary mechanism | PFAS removal strengths | Limitations vs activated carbon |

| Granular activated carbon (GAC) | Adsorption onto porous carbon surface epa+1 | Very effective for long‑chain PFAS; well‑proven at scale epa+2 | Shorter‑chain PFAS harder to remove; media replacement needed pubs.acs+2 |

| Powdered activated carbon (PAC) | Dosable adsorbent for rapid treatment pubs.acs+1 | Flexible, fast adsorption; good for emergencies pubs.acs+1 | Higher operating cost and sludge; not a standalone long‑term solution pubs.acs+1 |

| Ion exchange (IX) resin | Electrostatic attraction and sorption sciencedirect+1 | High capacity; strong performance for many PFAS species nature+2 | Media cost; brine or resin regeneration/disposal challenges pmc.ncbi.nlm.nih+1 |

| Reverse osmosis (RO) | Physical separation via semi‑permeable membrane keltren+1 | Up to very high PFAS removal, including short‑chain PFAS keltren+1 | Produces PFAS‑rich reject; higher energy and maintenance keltren+1 |

In many full‑scale installations, granular activated carbon is either the primary PFAS barrier or part of a treatment train where activated carbon polishes water after membrane or ion exchange processes, capturing residual organic contaminants and improving overall water quality. For home treatment, dual‑stage systems combining activated carbon with reverse osmosis are widely recommended to maximize PFAS reduction while still providing the taste and odor benefits associated with activated carbon.[4][15][6][1][3]

Industrial Uses of Activated Carbon for PFAS

Activated carbon plays a central role in industrial and remediation applications where PFAS contamination can be high, variable, or mixed with complex organic matrices. Specialized activated carbon grades and engineered systems target PFAS in surface water, groundwater, landfill leachate, industrial wastewater, and process water streams across multiple sectors.[10][8][5][16]

Typical industrial use cases for activated carbon PFAS treatment include:

- Manufacturing and process water

- Activated carbon systems are installed on incoming water to protect sensitive processes from PFAS, or on outgoing streams to ensure compliance with discharge limits and protect downstream ecosystems.[5][16][10]

- Industries such as metal plating, electronics, textiles, and automotive often deploy activated carbon along with other treatment steps to manage PFAS and broader organic loads.[6][16][10]

- Firefighting foam and remediation

- Firefighting foam (AFFF) is a major PFAS source at airports, military sites, and industrial facilities, where activated carbon is used for ex situ treatment of contaminated groundwater and surface water.[16][10][6]

- Granular activated carbon beds in pump‑and‑treat systems capture a wide range of PFAS compounds from remediation flows, with spent activated carbon then transported to specialized facilities for high‑temperature reactivation or safe disposal.[10][5][6]

- Landfill leachate and soil washing

- Activated carbon is integrated into treatment trains for PFAS‑laden leachate from municipal and industrial landfills, often in combination with coagulation, membranes, or ion exchange.[5][6][10]

- In soil washing projects, activated carbon polishing steps remove residual PFAS from extracted wash water, enabling recycling of process water and reducing overall environmental impact.[8][6][10]

For a global supplier of customized activated carbon solutions, these industrial applications provide opportunities to offer tailored activated carbon products (e.g., specific pore size distributions, raw material bases, and particle sizes) that match the PFAS profile and operational conditions of each client.[8][10][5]

Conclusion

Activated carbon filters do remove PFAS, and granular activated carbon is one of the most established technologies for reducing PFAS in both drinking water and industrial applications. Performance is especially strong for long‑chain PFAS, with well‑designed activated carbon systems achieving high removal efficiencies and, in some cases, PFAS levels below analytical detection, provided that media change‑out or reactivation is managed correctly.[1][2][3][7][5]

At the same time, activated carbon is not a universal, permanent solution: short‑chain PFAS are more challenging, water chemistry can limit adsorption, and PFAS captured by activated carbon must still be handled responsibly through regeneration or disposal. For many utilities, industries, and households, the most reliable strategy involves combining high‑quality activated carbon with complementary technologies such as ion exchange or reverse osmosis, guided by site‑specific PFAS data and regulatory requirements.[11][15][17][3][6][9]

FAQ: PFAS and Activated Carbon Filters

1) Do all activated carbon filters remove PFAS?

Not all activated carbon filters are designed or certified for PFAS removal, even though activated carbon as a material can adsorb many PFAS compounds. Some small household activated carbon pitchers and faucet filters focus on chlorine, taste, and odor and do not claim any PFAS reduction, so users should look for PFAS‑specific certifications or test data before relying on an activated carbon product for this purpose.[14][15][4][13]

2) Are granular activated carbon filters better than powdered activated carbon for PFAS?

Granular activated carbon filters are generally better suited for continuous, long‑term PFAS treatment in full‑scale systems because they allow controlled contact times, straightforward media replacement, and integration in fixed beds. Powdered activated carbon can effectively adsorb PFAS in batch or short‑term applications but usually requires higher doses and produces more sludge, making it less practical as a standalone, long‑term PFAS solution compared with granular activated carbon.[2][1][9][5]

3) How long do activated carbon filters last when treating PFAS?

The service life of an activated carbon filter for PFAS depends on PFAS concentrations, water quality, flow rate, and the type and amount of activated carbon used. Pilot testing and monitoring for breakthrough are commonly used to estimate change‑out intervals, and some utilities design multi‑column activated carbon systems that allow one bed to be taken offline for media replacement while others continue providing PFAS removal.[3][7][6][5]

4) Is activated carbon enough to meet the strictest PFAS regulations?

In many cases, high‑quality granular activated carbon systems can meet stringent PFAS regulatory limits, especially for long‑chain PFAS. Where water contains a mix of PFAS, including challenging short‑chain compounds, or where very low combined PFAS limits apply, utilities may combine activated carbon with ion exchange, reverse osmosis, or other advanced processes to ensure compliance.[17][7][6][1][2][3]

5) What happens to PFAS after they are captured by activated carbon?

Activated carbon does not destroy PFAS; it concentrates PFAS on the carbon surface, so the spent activated carbon is itself a PFAS‑containing waste that must be managed responsibly. Specialized high‑temperature reactivation or disposal routes are used to treat PFAS‑loaded activated carbon, and industrial suppliers now offer certified reactivation services to break down PFAS molecules and recover usable activated carbon where regulations and technology allow.[11][6][10][5]

Citations:

[1](https://www.epa.gov/sciencematters/reducing-pfas-drinking-water-treatment-technologies)

[2](https://www.chemviron.eu/solutions/pfas-removal/)

[3](https://www.nature.com/articles/s41545-025-00457-3)

[4](https://www.health.state.mn.us/communities/environment/hazardous/topics/pfashometreat.html)

[5](https://norit.com/applications/pfas)

[6](https://pfas-1.itrcweb.org/12-treatment-technologies/)

[7](https://pmc.ncbi.nlm.nih.gov/articles/PMC8864563/)

[8](https://www.hyerainc.com/pfas-adsorption-and-remediation)

[9](https://pubs.acs.org/doi/abs/10.1021/acsestwater.4c00901)

[10](https://www.jacobi.net/pfas-industrial-water-treatment/)

[11](https://pmc.ncbi.nlm.nih.gov/articles/PMC12260480/)

[12](https://www.sciencedirect.com/science/article/abs/pii/S0043135422011435)

[13](https://www.livingwhole.com.au/do-carbon-filters-remove-pfas/)

[14](https://pbswisconsin.org/news-item/what-should-i-do-about-pfas-in-my-water/)

[15](https://superfund.ncsu.edu/wp-content/uploads/sites/156/2021/08/NCSU_PFASfilters_infographic.pdf)

[16](https://www.calgoncarbon.com/app/uploads/Industrial-Remediation-PFAS-Final-1.html)

[17](https://keltren.com/blog/the-science-behind-pfas-removal-activated-carbon-vs-reverse-osmosis/)

[18](https://www.reddit.com/r/WaterTreatment/comments/126yqpu/does_activated_carbon_removereduce_pfas/)

[19](https://crystalquest.com/blogs/home-water-filter/pfas-filtration-guide)

[20](https://orthosfilters.com/pfas-removal-with-granular-activated-carbon-gac-and-ion-exchange-media/)